QUALITY ASSURANCE PROGRAM OVERVIEW

Quality Assurance is woven into everything we do at Source. You can rest easy, knowing that when your product ships, it meets your product specifications. We focus on five critical areas:

- The Right Factory: We identify, audit, and select only qualified manufacturers and sub-contractor partners.

- The Tech Pack: We deploy our quality engineers and technicians to define the requirements and to mentor the factories on quality improvements and certifications.

- The Tooling: We provide daily on-site project management, problem-solving, and support on the ground of our factory partner network to make sure the tooling, molds, and production jigs are made right.

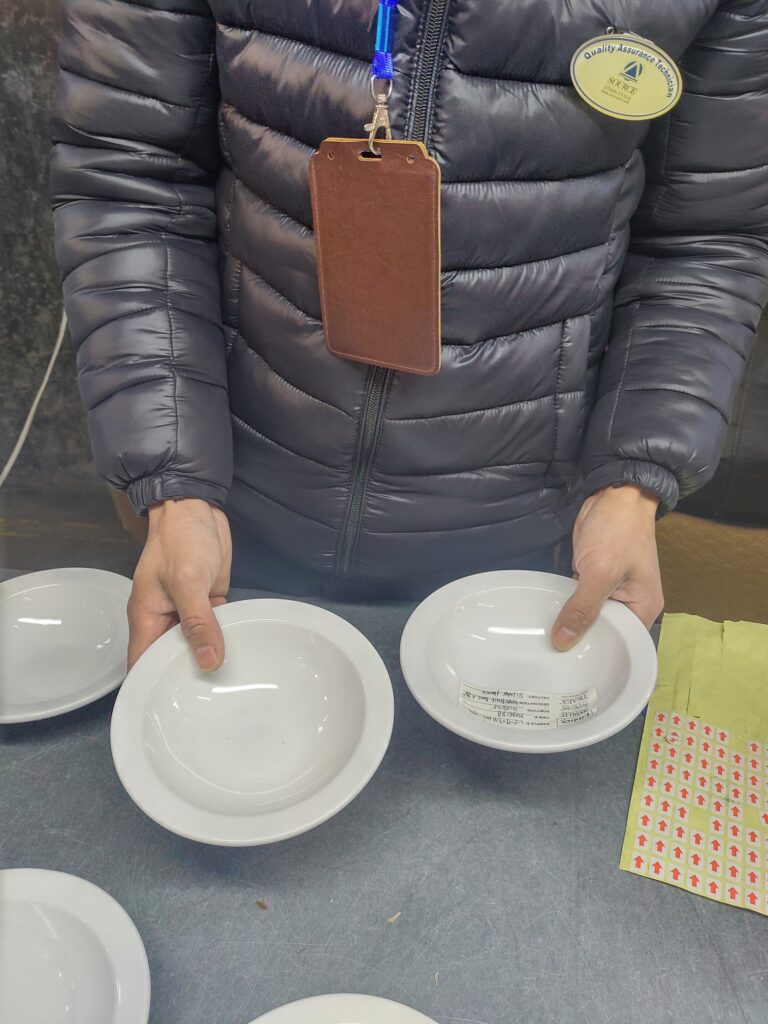

- Product Quality Audits: We validate that the product satisfies all requirements for materials, dimensions, appearance, workmanship, packaging, and other testing and compliance standards.

- The Results: We celebrate our successes and continuously improve our processes, personnel, and technologies.

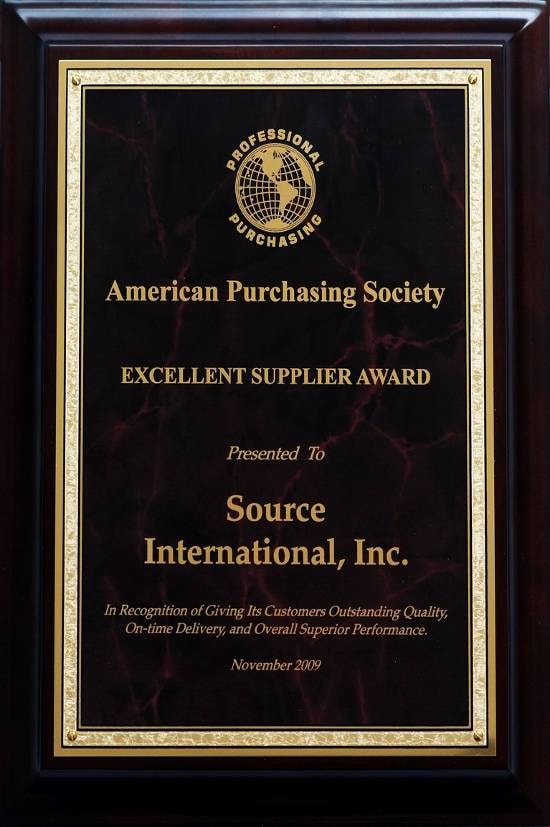

Award-Winning Quality Program

The Source Quality Management System (QMS) is a proven quality system that balances risk and cost factors to assure affordable, on-spec products. By employing American military standards (MIL-STD-1916 and ANSI/ASQ Z1.4) the Source QMS achieves low defect rates (less than a quarter of one percent) and the highest levels of reliability and confidence on volumes that exceed 20,000 containers per year.

Quality that meets your standards begins with planning. The Source QMS focuses on clearly defining your expectations and requirements with a strictly controlled quality documentation process known as the Product Tech Pack (PTP). Our highly trained in-country teams of engineers and technicians perform complete bi-lingual documentation to assure that all specs and certifications are met before the product ships.

Multiple supplier awards, Six Sigma Black Belt certifications, supply industry designations, and ongoing customer successes reinforce the value of a Source International partnership. You can expect a consistent and universal process for all products we supply to you and one conducted with the highest level of ethical standards. Whether it’s a simple or highly technical product, our process is the same.

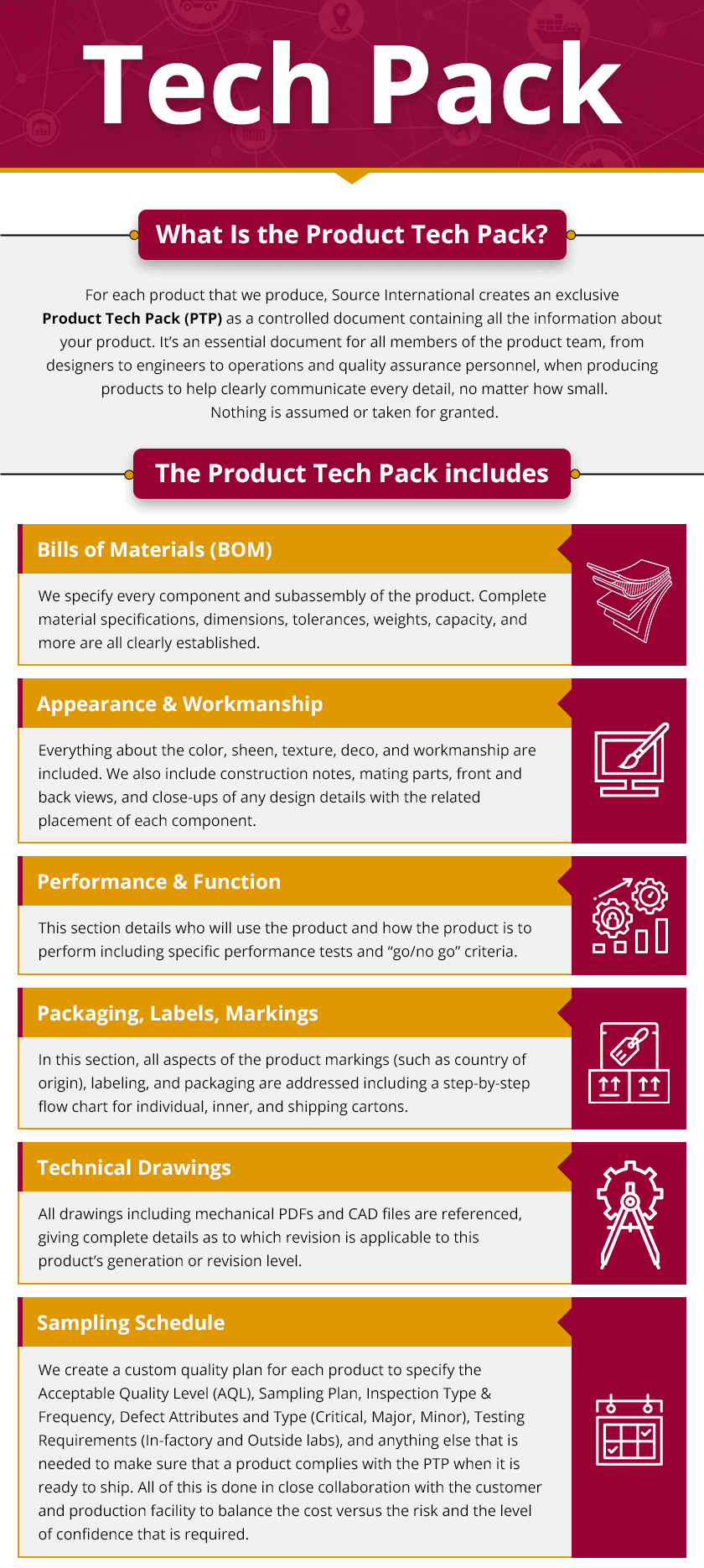

THE CORE OF THE SOURCE QUALITY ASSURANCE PROGRAM IS THE PRODUCT TECH PACK

Staff Training is Key

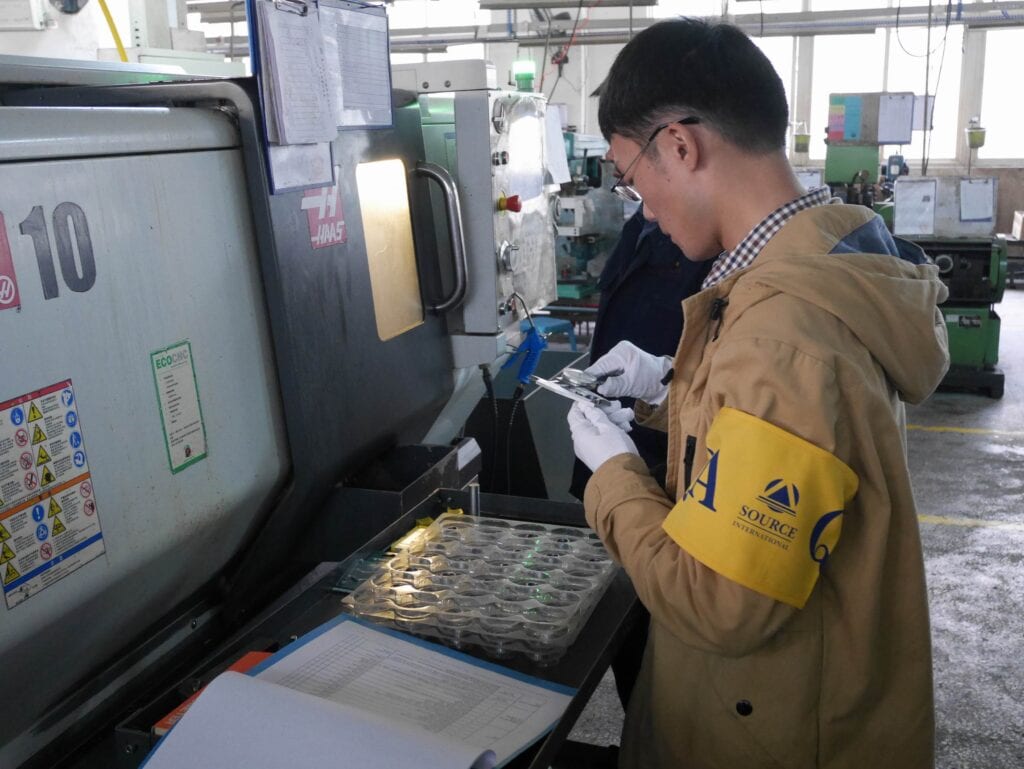

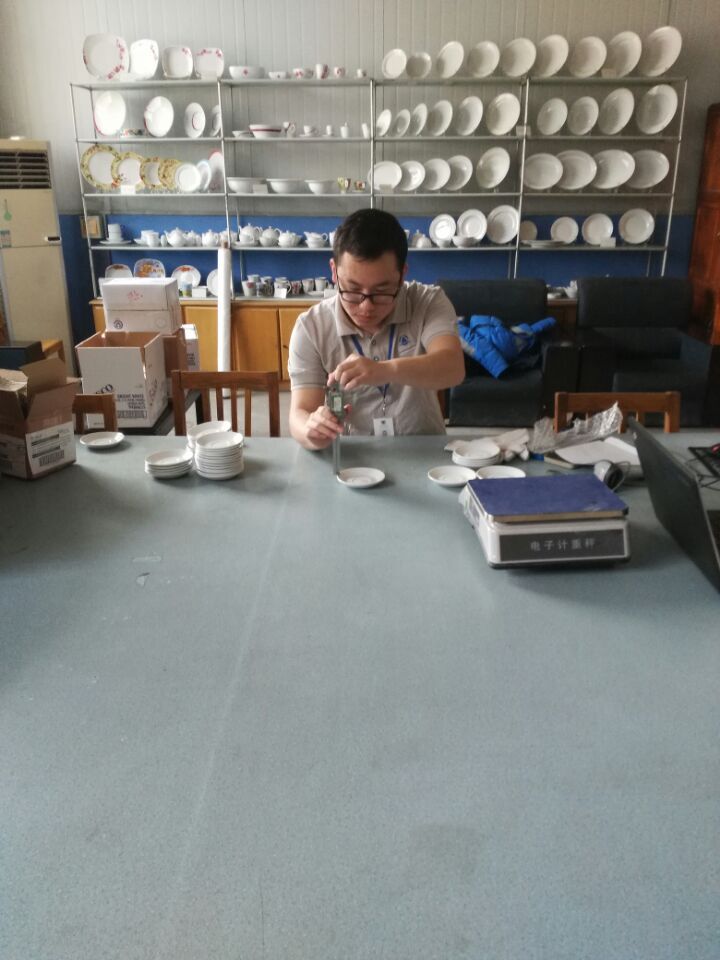

The training of our Quality Assurance Engineers (QAE) and Technicians (QAT) is key to our success. The process begins by drafting and getting approval from customers and factories on the Product Tech Pack (PTP). The PTP serves as the filter through which all our inspection, testing, and auditing functions are performed before, during, and after the manufacturing process.

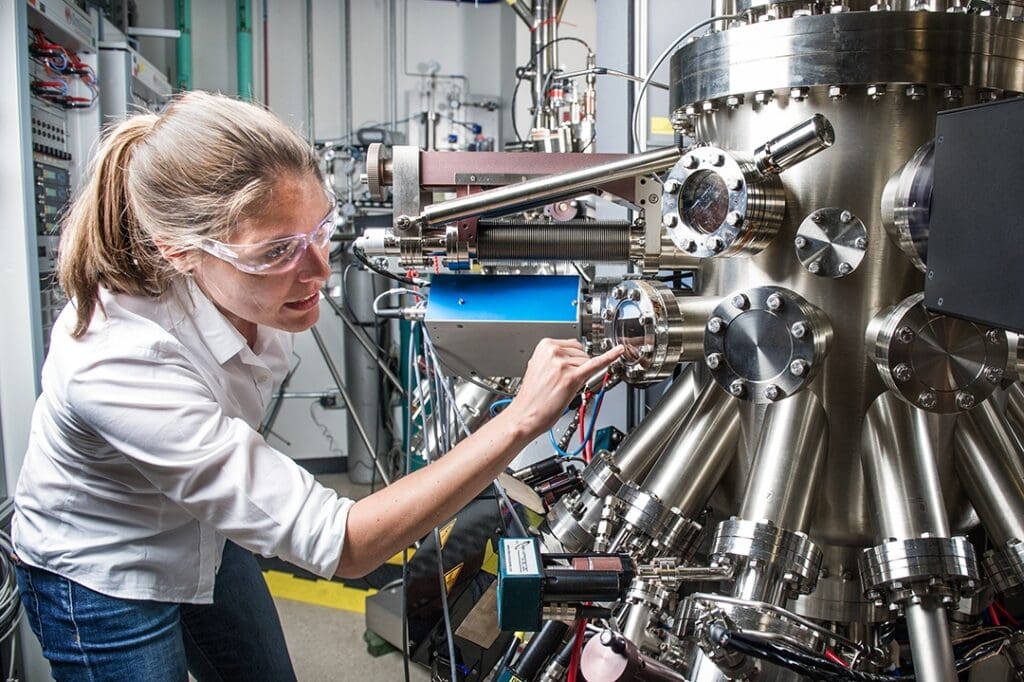

Our inspection process includes a First Production Approval (FPA) for all new products, Raw Material Validations (IQC), Work-In-Process Audits (IPQC), and thorough Pre-Shipment Inspections (PSI). In addition, we perform in-factory lab testing on-site on the factory floor and in independent testing in internationally certified labs to ensure that you receive just what you order.

Complete factory auditing and internal auditing programs identify any weaknesses in our systems, and our personnel and allow us to initiate corrective actions before issues are perpetuated. Factory Scorecards provide valuable independent KPI metrics to base future product quality decisions.

A Complete Program That Covers All the Bases

- Complete Specification Documents & Quality Planning (PTP)

- Potential Failure Mode Effects Analysis (PFMEA)

- Pre-Production Samples (PPS)

- First Production Approval (FPA)

- In-Factory Lab Testing

- Incoming Quality Control (IQC)

- In-Process Quality Control (IPQC)

- Pre-Shipment Inspection (PSI)

- Shipping Samples (SSI)

- Independent Lab Testing

- Factory Capability Audits

- Social & Environmental Compliance Audits

- C-TPAT Security Audits

- Container Loading Audits

- Retailer Specific Audits

We welcome you to contact us or visit one of our offices to learn firsthand about the scope of our operations and quality programs and for more information on how we can add value to your offshore supply chain.