Plastic Injection Molded Products

Source International – Plastic Injection Molded Products

Precision Plastic Injection Molded Products From Source International

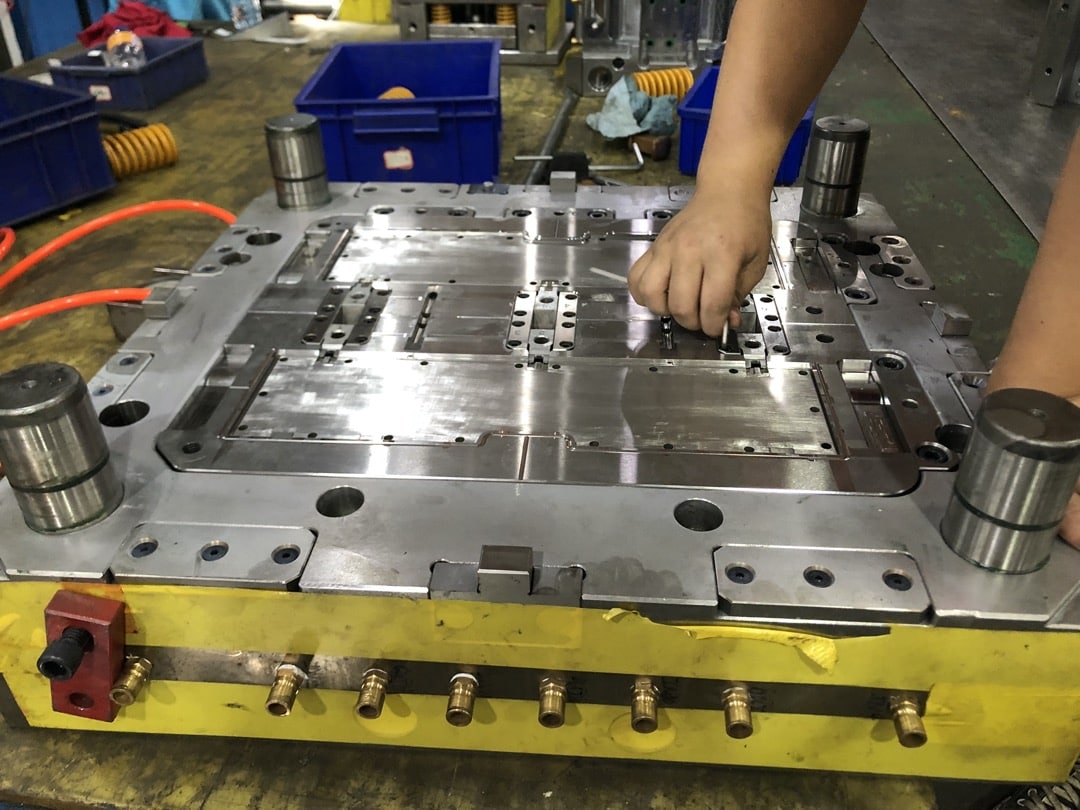

Plastic Injection Molded Products can be produced in a variety of shapes (simple to highly complex) and sizes (micro to large), suitable in many different industries (from consumer electronics to large industrial equipment). Source has been providing plastic injection molded products for our customers for over 25 years. To make high-quality injection molded parts, it all starts with high-quality injection mold and Source has partnered with dozens of injection mold manufacturers to produce key components through Wire EDM, CNC Machining Center, Grinder, etc.

Our ISO 9001 certified facilities focus on the most advanced, state-of-art plastic injection equipment with machines ranging in size from 80 ton to 2400 tons giving us the capability to deliver a diverse set of parts for a wide range of industries, including agriculture, automotive, industrial machines, HVAC, and many others. Common material used at our factories are PE, PP, PVC, PS, ABS, PA, POM, PC, and many others.

Starting with your AutoCAD, IGES, PDF, or SolidWorks file, our expert team produces your custom parts with tight tolerances and that always meet your specifications. Regardless of the complexity of your design, we’ll find the best way to meet your needs in a timely, cost-effective manner.

Watch this short video here for a good overview of injection molding process.

Plastic Injection Molded Products

The shapes, sizes, and materials for plastic Injection Molded products are practically unlimited and it is a highly repeatable manufacturing process. The second part you produce is going to be practically identical to the first one which produces consistent tolerances, brand consistency, and part reliability in volume production. When molding thermoform plastics into products and component parts, one principal advantage of injection molding is the ability to scale production. Typically generating as few as 2000 injection molded parts justifies the development of an injection mold tool. The one-time cost of mold making is quickly offset by high capacity to achieve extremely low part prices. Once the initial costs have been paid the price per unit drops as more parts are produced. The injection molds and molding machine sizes are engineered to meet production demands based on the cycle time. Plastic Injection Molding also produces low scrap rates relative to traditional manufacturing processes since there is very little material wasted as scrap like CNC machining. The scrap that is generated comes primarily from four areas: the sprue (channel that guides molten plastic from the nozzle of the injection molding machine), the runners (system of channels that meet up with the sprue), the gate locations (part of the channel after the runner that leads directly into the part cavity), and flash (leakage of material where the mold closes together). While plastic injection molding product applications have many advantages in part cost, efficiency, and scalability, some disadvantages are the one-time tooling costs and longer lead-times.

Part Design & Prototyping

Parts should be designed from day one with the injection molding process in mind to simplify the geometry and minimize assembly. To the extent that you can design assembly out of the process, you will save money on the cost of labor and pay dividends down the road. Source’s injection molding expertise can help you with that. Once the preliminary design of the part has been decided upon, using a 3D Printer, CNC machining, or other rapid prototyping techniques, we create a one-off of the actual part for evaluation prior to tool making. While oftentimes, the prototype is in a different material than the final part will be constructed in, seeing and holding the physical part leads to insights that are not as obvious in a digital file and facilitates the approval process. Large undercuts require an experienced design to avoid and can often add costs to the project whereas over-molded parts can combine more than one part into one mold. A new part will typically go through various iterations and prototypes before the final design is approved and released for production.

Precision Plastic Injection Molding Product Applications

Source International offers a wide range of precision plastic injection molding design, tool making, precision injection molding and packaging and delivers on-time, on-spec, every time. Our high-performance systems are engineered for eco-friendly, low energy consumption with super-accurate repeatability within extremely tight tolerances. Contact our team today to check your precision part specifications against our capabilities.

Getting the Product and Mold Design Right

Since the up-front costs of creating a new plastic injection molded part is a substantial sunk cost investment it is critical to get the design of the part and the mold (which go hand-in-hand) right the first time. Source International uses best practices for creating new plastic injection molding product applications and in the production of precision plastic injection parts.

Molding Test are required to make sure the mold is well manufactured to meet the manufacturing needs and the parts are produced to the specs.Typically two or three or more trials are needed before giving the mold a green light for mass production. The mold may need to be sent back to the shop for modification or twisted during these trials. Molding Technician also fine-tune the process parameters (pressure, cooling time, etc.) during these trials, and then document put those in work instructions, this is to insure that we achieve consistent molded parts for every batch.

Mold Design Considerations

Once the prototype has been approved the mold design and construction can begin. Designing an efficient plastic injection mold tool for production requires many considerations. The type of mold base, the number of cavities, the type of steel are all important considerations.Because tools are typically made out of steel it can be difficult to make changes later. If you want to add plastic to the part, you can always make the tool cavity larger by cutting away steel but if you are trying to take away plastic you need to decrease the size of the tool cavity by adding metal to it (mirror image) which is extremely difficult and may lead to undesirable cosmetic issues. Good mold design will minimize cycle time as much as possible with hot runner technology, efficient slides, and other techniques. Cutting a few seconds from your cycle time can translate into big savings, especially when you’re producing millions of parts.

Mold Construction

The type and harness of steel is a primary consideration for tool life and efficiency. Harder steels produce more parts before reaching the end of their useful life, however they are typically more expensive. Injection molding necessitates uniform wall thickness. Keeping walls from being too thick is important to prevent inconsistencies in the cooling process resulting in defects like sink marks. And, the thicker the walls the more material you will use, the longer the cycle time will be and the higher your cost per part will be. Conversely, if wall thickness is too thin, you might experience trouble filling the mold tool (resulting in gaps or short shots).

Mold Debugging

Debugging is a necessary step in any new plastic injection mold and involves refining all details in the injection mold tool prior to mass-production in an injection mold manufacturing plant. All parameters of the injection process must be measured and the parts evaluated closely before being released for final hardening of the steel to make the tool ready for mass production.

Recycled Material

Plastic materials from the waste areas can be recycled and used again. Sometimes this happens right on the factory floor. They grind up the sprues/runners and any reject parts. Then they add that material back into the raw material that goes into the injection molding press. This material is referred to as “re-grind”. We strictly limit the amount of regrind that is allowed to be placed back into the press since some performance properties of the plastic can degrade as it is molded over and over. Other products with less demanding applications can be made from more re-grind to lower the cost or appeal to more eco-friendly consumers.

SUBSCRIBE TO OUR NEWSLETTER

Talk With Our Supply Chain Experts

SCHEDULE A CALLSOURCE INTERNATIONAL OPTIMIZES SUPPLY CHAINS

Whatever your procurement needs may be, Source International provides commodity and supply management expertise to allow you the most globally competitive prices combined with the best quality (always on-spec) and an on-time delivery record unmatched in the industry.

Send us an email to find out how we can add value to your global supply chain to save you time and money while increasing overall efficiency and product quality.

CNC Mold Making Machine

CNC Mold Making Machine Mold Assembly

Mold Assembly First Part Inspection

First Part Inspection Wire EDM Machine

Wire EDM Machine