Our process-driven professionals are focused on your success.

THE BEST PROCESS

Our award-winning product management process provides a proven contract manufacturing solution with complete documentation and a world-class operations cloud portal.

THE BEST PEOPLE

We have a long-tenured, professional staff with broad industry experience and we train them continuously. A large segment of our team has a tenure of more than 5 years. Some have 10, 15, and even 20 years of service!

COMPELLING TRACK RECORD

Day after day, we deliver over-the-top service and exceptional quality products on time and on budget. Our team focuses on your success and we are accountable through our ironclad satisfaction guarantee.

We know that transparency and control are important to you. We provide you with global access with local control, as well as 24/7 visibility to your supply chain.

OUR CUSTOMERS SAY IT BEST

< CLICK TO SCROLL THROUGH OUR ACCOLADES >Exceptional Quality Products from an Exceptional Company

Source International takes the risk out of offshore contract manufacturing. We offer nearly limitless capacity. There will be no misunderstandings about quality standards or concerns about raw material availability. And, there will be no delivery black holes.

We manage the complexities of the complete manufacturing supply chain and give you peace of mind by:

- Identifying and qualifying the right factory

- Verifying the materials, tolerances, and workmanship

- Auditing and testing the production

- Certifying the performance requirements

- Controlling the delivery schedule

- Benchmarking and employing best practices

Ultra-modern facilities, cutting-edge capabilities.

Source International makes it easy to double or triple your current manufacturing capacity quickly and reliably with our contract manufacturing programs. Every day we solve problems of tight tolerances, complex assemblies, and hard-to-find materials and components.

You can add our certified supply management, engineering, and quality professionals to your team to tackle your most perplexing product manufacturing challenges. We are on-call at your convenience.

Expect a process that is consistent and universal to all products that we manufacture. The results are guaranteed. And you are protected because we never work with competing customers in the same industry.

See how our contract manufacturing programs can give you a competitive advantage.

Source International makes offshore manufacturing easy

SCHEDULE A CALL WITH OUR EXPERTS

The Right Factory

The Tech Pack

The Tooling

The Quality Process

The Results

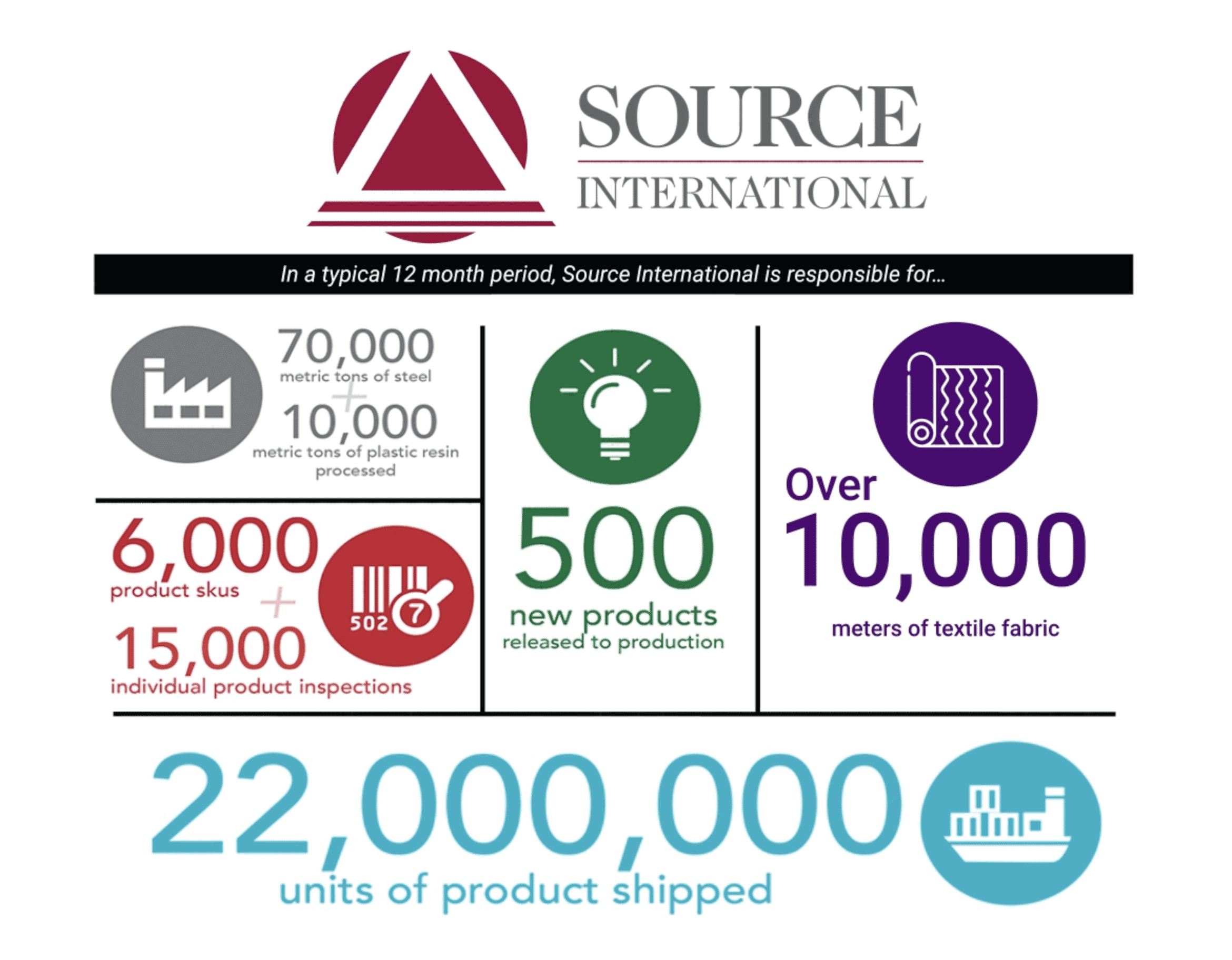

OUR ANNUAL VOLUMES GIVE US AN ECONOMY OF SCALE WE PASS ALONG TO YOU