At Source International, we provide comprehensive computer numerical control (CNC) machining services to deliver custom, tight-tolerance products for diverse industries. Our client base ranges from agriculture to aerospace, and this multi-industry background has given us extensive experience with a broad spectrum of material options, part designs, and industry regulations.

Using advanced equipment, our expertise in various CNC machining techniques, and our clients’ AutoCAD, SolidWorks, IGES, or PDF design files, we’ll manufacture customized products per your exact specifications and unique design requirements. Learn more about our CNC machining services and how Source International achieves extra-tight tolerances and cost-effective solutions while reducing your time to market.

CNC Machining Techniques

The CNC machining process incorporates automation into part manufacturing, relying on computer-controlled equipment and tooling to efficiently produce high volumes of precise, repeatable parts. Our state-of-the-art facility is equipped with 3-, 4-, and 5-axis CNC machines, benefitting our clients through enhanced part quality as well as reduced costs and lead times. Using the following CNC production methods, we excel at tight-tolerance parts in simple to complex geometries.

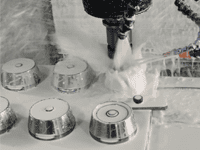

Boring, Drilling, and Tapping

Boring, drilling, and tapping are three effective methods for generating precisely shaped, positioned, and threaded holes in a material or workpiece. Using these techniques, we’ll create holes in custom sizes per your specifications, ensuring accuracy and tight tolerances for optimal component fit in products like industrial equipment enclosures and engine blocks.

Electrical Discharge Machining (EDM)

To create accurate cuts and detailed designs in hard metal materials, we utilize our EDM capabilities. EDM is a no-contact process that uses electrical discharges to make cuts without putting substantial stress on a material. At Source International, our team creates extremely precise products for medical and aerospace applications through EDM.

Lathing and Routing

These subtractive manufacturing techniques precisely shape parts by cutting away excess material. Lathing is ideal for creating cylindrical shapes, and routing is beneficial for producing complex designs out of plastic or composite materials. Clients choose our lathing and routing services for bushings, shafts, tubing, and other components.

Milling

The CNC milling process is well suited to anything from brackets to engine components, producing repeatable, tight-tolerance parts. Source International provides precision 5-axis milling services to shape workpieces into complex geometries. Our equipment’s single-setup machining capabilities enable us to increase efficiency and reduce turn times without sacrificing part accuracy.

Cutting: Plasma, Waterjet, and Laser

We have multiple options for cutting through materials, depending on part design and material composition. Plasma cutting is a fast and economical metal fabrication option that achieves cuts using a jet of hot plasma. Waterjet cutting instead uses a high-pressure water stream, producing intricate cuts in heat-sensitive materials without causing thermal distortion. As for laser cutting, a concentrated beam of light generates precision cuts with minimal material waste.

Grinding: Surface and Cylindrical

Surface grinding, one of our finishing services, results in a flat surface finish on a part. Alternatively, cylindrical grinding is applicable for refining the surfaces of components like bearings and shafts. These grinding processes result in smooth-surface parts capable of meeting the stringent standards in markets like aerospace, medical, and industrial.

Applications of CNC Machining

Companies across industries trust Source International for precision CNC machining services, extensive contract manufacturing capabilities, and extra-tight-tolerance parts. We routinely serve the following industries with CNC machining:

- Aerospace. CNC machining allows us to produce tight-tolerance aircraft and satellite components with a good strength-to-weight ratio for meeting strict design parameters.

- Agriculture. Source International fabricates heavy-duty parts capable of resisting degradation or corrosion in agricultural applications.

- Automotive. We use CNC machining to create brackets, engine blocks, and various performance components for vehicles.

- Industrial equipment. For the industrial sector, our team produces anything from machine tool parts to shafts and gears.

- Medical. We machine high-quality parts for the medical industry, ranging from orthopedic implants and prosthetics to surgical tools.

Choosing Source International for Your CNC Machining Needs

By partnering with Source International, you’ll benefit from the following:

- Quality and precision you can trust. With our ISO 9001-certified facility, investments in high-precision equipment, and an award-winning quality program, Source International is committed to quality in products and services alike.

- Cutting-edge technology and manufacturing capabilities. In business since 1988, our company has the advanced CNC equipment and expertise necessary to ensure precision and operational efficiency. Our extensive service offerings include CNC machining, sheet metal fabrication, plastic injection and rubber compression molding, die casting, forging, surface finishing, and assembly.

- Global supply chain and competitive pricing. We maintain strategic partnerships in the US, China, and Vietnam to streamline your supply chain and offer scalable and cost-effective machining solutions for projects from prototyping to high-volume production.

- Customer-centric approach. The Source International team will work closely with you to understand your custom product vision, integrating it seamlessly with our turnkey machining processes.

Interested in learning more about our extensive CNC machining services? Contact us today for additional information or to request a quote for your next project.