Why Us For Your Product Sourcing & Manufacturing?

Product Sourcing & Manufacturing Program Overview

Our strategic factory sourcing and management process aims to constantly improve all of our suppliers’ activities for increased operational excellence.Factory Sourcing and management is one of the most critical aspects of any contract manufacturing program. It is the lifeline of any product business. In this age of global supply chains, you have access to unprecedented opportunities; however, the path is teeming with pitfalls. It’s extremely difficult to find the ideal factory that you can trust to make your product at the price, quality, and scale you need and to make it sustainably.

As organizations encounter growing pressure to manage costs, improve quality, and hold to predictable delivery schedules, there are many black holes that you can put lots of time and energy into with little or no result. Our strategic factory sourcing and management process is ongoing and intended to discover, prioritize, improve, and constantly re-evaluate all of our suppliers’ activities for increased operational excellence.

We Create Partnerships for Your Success

Transparency and control are critical in your offshore supply management programs. With Source International operating as your supply management partner, you have complete transparency of the process, along with all of the benefits of having a dedicated staff to look out for your interests. You’ll get the access you need without the headaches of travel, time zone differences, and language barriers.

We are your boots-on-the-ground, a team of qualified and trained bilingual staff to act in your interests and your interests only. In addition, the Source International SIS web portal offers you 24/7, real-time access to quotes, orders, quality, logistics, and all other details of your global product manufacturing operations from anywhere in the world.

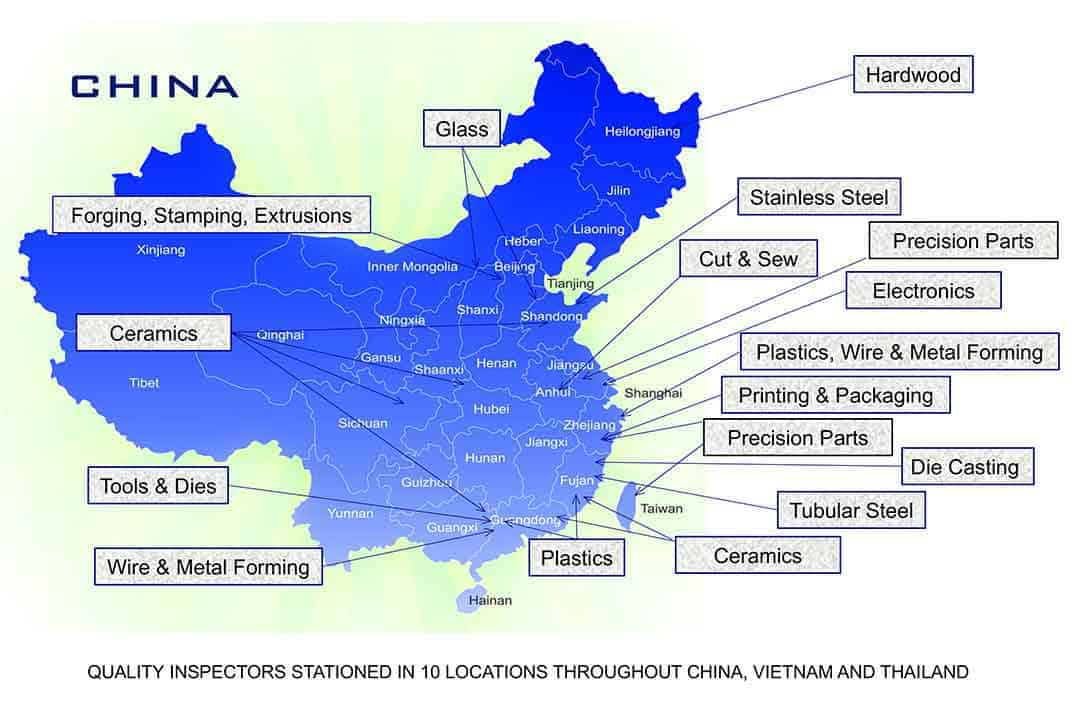

Locations of Core Factories in China

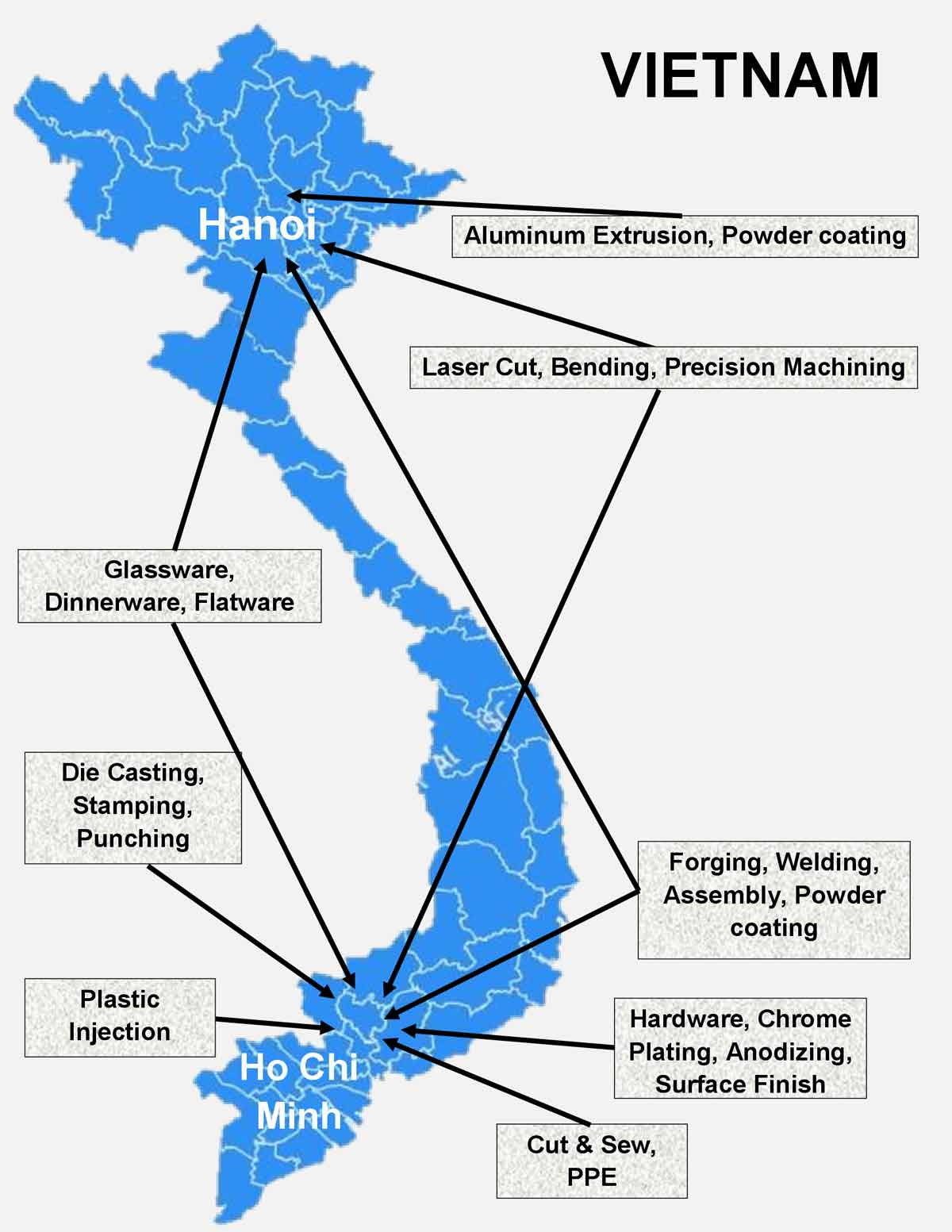

Locations of Core Factories in Vietnam

Why Use Source International for Your Product Sourcing & Manufacturing?

By building long-term relationships with world-class accredited and certified factories, we offer a wide range of manufacturing capabilities in our factory sourcing program and source virtually anything under 1 umbrella.

Our Factory Sourcing and Manufacturing programs deliver a fully transparent supply chain network of fully vetted and approved suppliers. And, in our cloud-based online portal you will be able to monitor the progress of your project and important documents from anywhere in the world, in real-time, 24/7.

We help organizations leverage their supply chain efforts to enhance their operational excellence and effectively process an ever-increasing data stream.

Our management programs follow industry best practices to achieve our sourcing objectives using an information-based methodology for understanding the best overall strategic suppliers across a wide range of industries. And we monitor the progress and quality of your project on-site as necessary.

This helps our customers improve sustainability, withstand competition, and ultimately improve their bottom-line results significantly to extend the most competitive pricing to their clients. The objective is to look beyond delivery time and daily price challenges with a complex process of strategic sourcing and business collaboration that helps you understand and control your supply chain more fully.