PRODUCT DEVELOPMENT OVERVIEW

Product Development, when it’s done right, makes a huge difference in the cost and manufacture-ability of new products. It’s a core competency of Source International. Our proven step-by-step process spurs innovation as we methodically move a product from formulating the initial concept to developing the Product Tech Pack Document (PTP), tooling, and releasing it to the production floor.

We develop more than 500 new products each year, and we have the know-how and experience to avoid common pitfalls that less experienced companies often make. Our many years of rich new product development expertise help us learn from past mistakes and minimize risks when developing new products.

We can also help you incorporate into your products important aspects of the Digital Transformation Revolution that rapidly disrupt the product development landscape, such as the “internet of things.” Trust the development of your next new product project to Source International. No one does it better!

ALL PRODUCT DEVELOPMENT WORK LEADS TO THE FINAL APPROVAL AND “FREEZING” OF THE DESIGN

The Source Team of engineers, product specialists, and quality technicians have new product development experience in a wide variety of materials, processes, and industries. Our agile process balances the product design needs with manufacturing requirements to produce a predictable, sustainable product that can be manufactured efficiently. The right combination of function, style, cost, packaging, and cost make all the difference and yield benefits throughout the life cycle of the product.

ONCE THE PRODUCT DEVELOPMENT PROCESS IS COMPLETE, THE NEXT STEP IS TO DEVELOP, APPROVE, AND ISSUE OF THE PRODUCT TECH PACK (PTP)

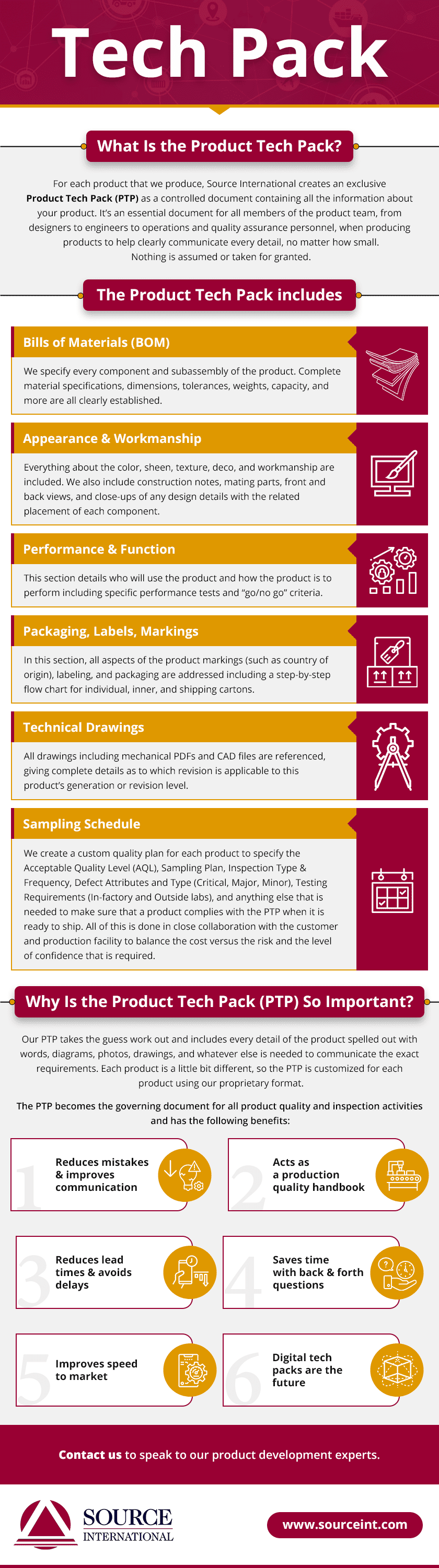

What Is the Product Tech Pack?

For each product that we produce, Source International creates an exclusive Product Tech Pack (PTP) as a controlled document containing all the information about your product. It’s an essential document for all members of the product team, from designers to engineers to operations and quality assurance personnel, when producing products to help clearly communicate every detail, no matter how small. Nothing is assumed or taken for granted.

The Product Tech Pack includes:

Bills of Materials (BOM): We specify every component and subassembly of the product. Complete material specifications, dimensions, tolerances, weights, capacity, and more are all clearly established.

Appearance & Workmanship: Everything about the color, sheen, texture, deco, and workmanship are included. We also include construction notes, mating parts, front and back views, and close-ups of any design details with the related placement of each component. For example, something like color which is often very subjective, is quantified through tools like our Spectrophotometer. And standards of coating such as powder coatings can be quantified using the PCI Visual Smoothness Standard Panels.

Performance & Function: This section details who will use the product and how the product is to perform including specific performance tests and “go/no go” criteria. What should be the life of the product, what weight should it be able to withstand, how fast should it go, etc? Everything is specific to the product, its cost structure, and what the product designer intends with the design.

Packaging, Labels, Markings: In this section, all aspects of the product markings (such as country of origin), labeling, and packaging are addressed including a step-by-step flow chart for individual, inner, and shipping cartons.

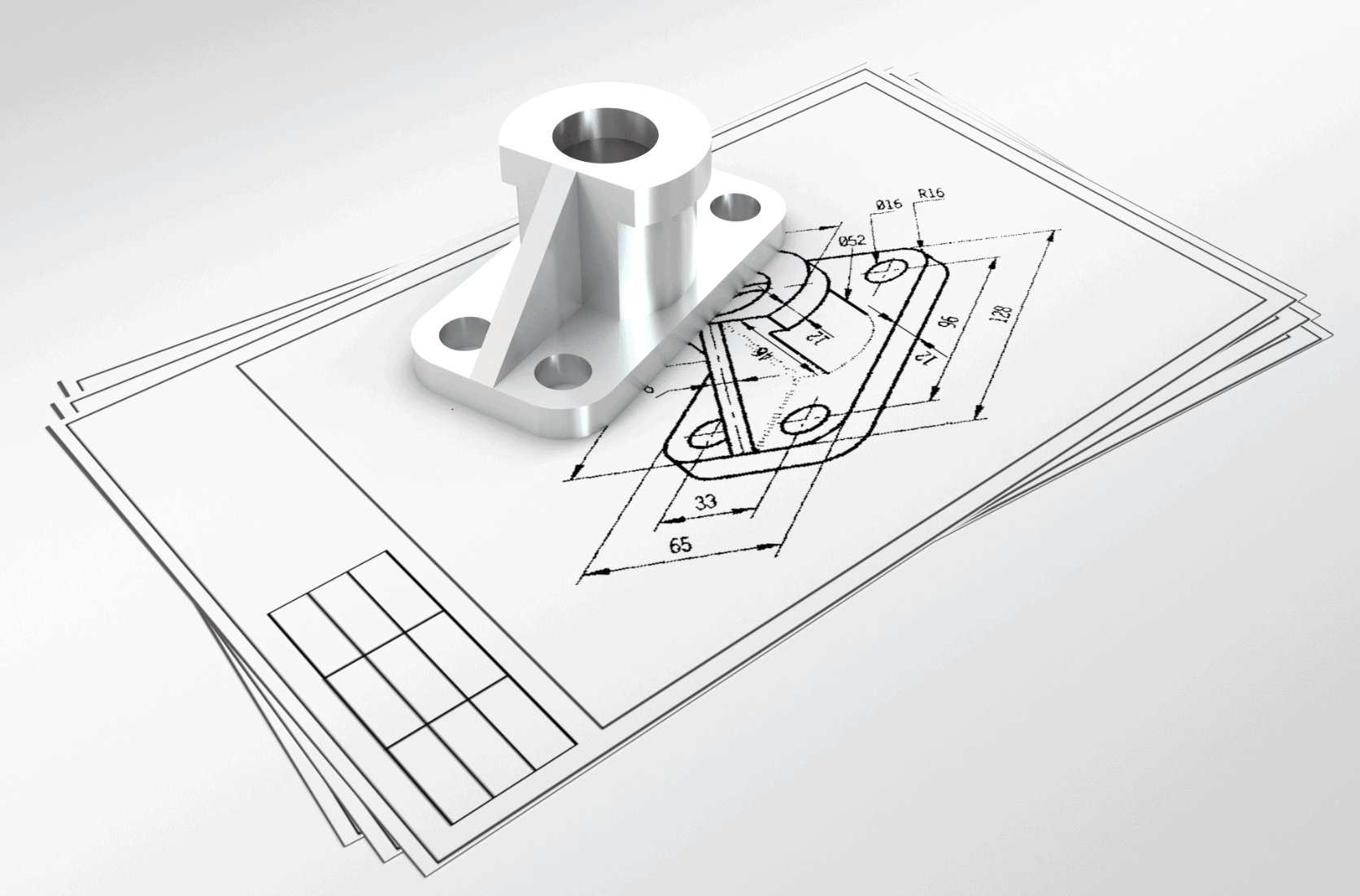

Technical Drawings: All drawings including mechanical PDFs and CAD files are referenced, giving complete details as to which revision is applicable to this product’s generation or revision level. Oftentimes changes are made to a product to improve or add or subtract features. So, since our PTP is a controlled document, there is no confusion about which drawing is applicable to the production.

Sampling Schedule: Each product is a little different but in general most PTPs require the following samples. These may be increased, added to, or eliminated based on factors of costs, shipping, stage of a product life cycle, and other needs.

- Prototype or Hand Counter Sample: Commonly made during the product development process.

- Pre-Production Sample: Normally made from production tooling and produced prior to mass production in a sample run or pilot production.

- Shipping Samples: Sometimes these are sent from the front of production as a fail-safe but most commonly they are kept at the factory or in our Asia office following production for future reference in case there is a question about the shipment and for future production reference.

Quality Plan & Checklist: We create a custom quality plan for each product to specify the Acceptable Quality Level (AQL), Sampling Plan, Inspection Type & Frequency, Defect Attributes and Type (Critical, Major, Minor), Testing Requirements (In-factory and Outside labs), and anything else that is needed to make sure that a product complies with the PTP when it is ready to ship. All of this is done in close collaboration with the customer and production facility to balance the cost versus the risk and the level of confidence that is required.

Why Is the Product Tech Pack (PTP) So Important?

Our PTP takes the guess work out and includes every detail of the product spelled out with words, diagrams, photos, drawings, and whatever else is needed to communicate the exact requirements. Each product is a little bit different, so the PTP is customized for each product using our proprietary format.

We take our time and collaborate closely with customers and the production personnel to make sure every detail is included. This helps us to avoid communication breakdowns, mistakes and delays. Especially in the cross-cultural environment that we operate in, where one person’s idea is often very different from another person’s idea.

So, in short, we make sure to get it right the first time, making it universal across time zones, language, and cultural differences. The PTP becomes the governing document for all product quality and inspection activities and has the following benefits:

- Reduces mistakes and improves communication.

- Acts as a production quality handbook.

- Reduces lead times and avoids delays.

- Saves time with back and forth questions.

- Improves speed to market.

- Digital tech packs are the future.