Product Assembly Experts

Source International – Product Assembly Experts

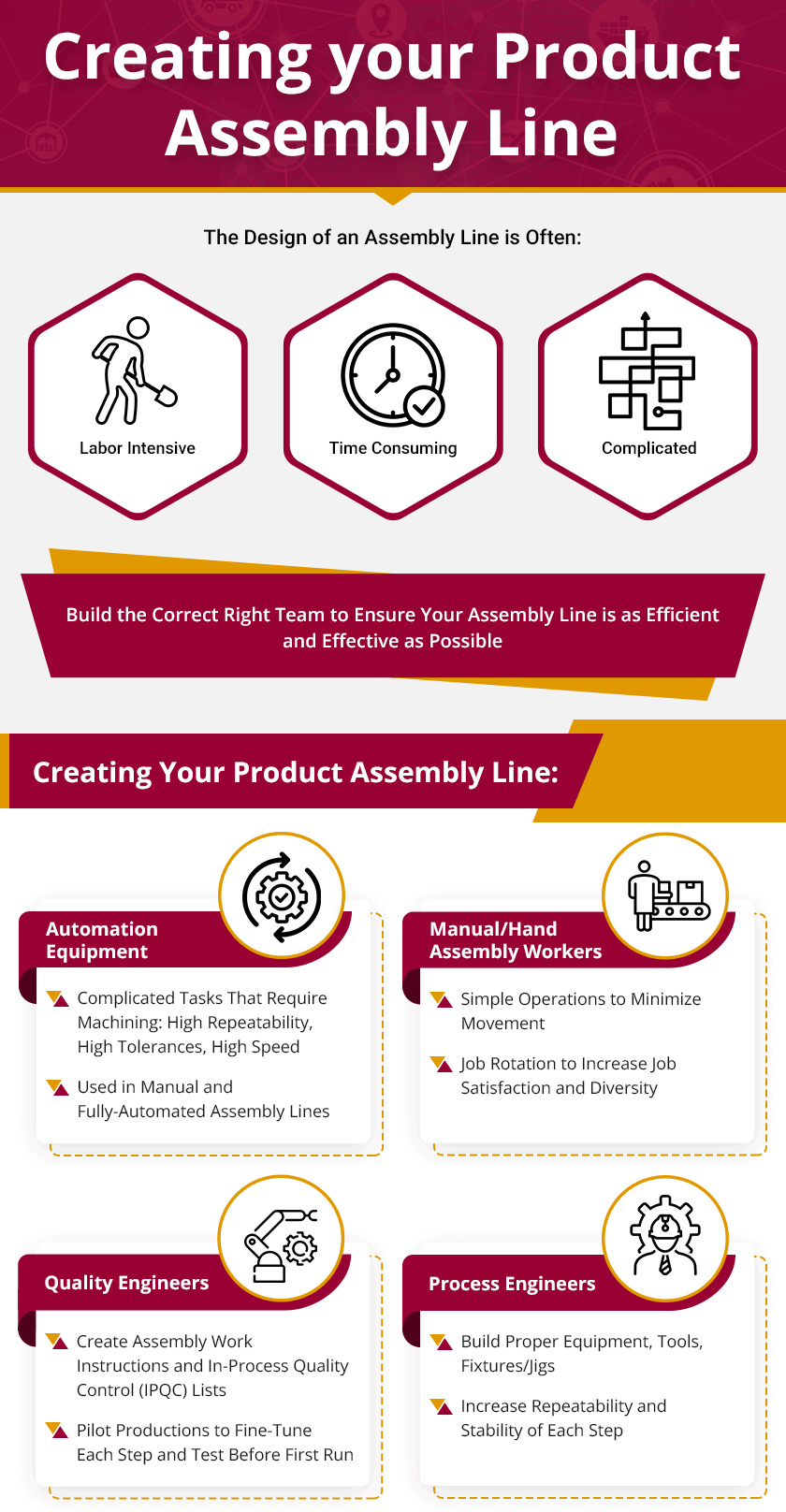

WHY IS AN EFFICIENT PRODUCT ASSEMBLY LINE SO IMPORTANT?

Product Assembly is one of the most critical aspects of the success of product manufacturing because its often the most labor-intensive, expensive and time-consuming process. The design for a product assembly line is determined by analyzing the steps necessary to manufacture each product component as well as the final product. All movement of material is simplified, with no cross flow, backtracking, or repetitious procedures. Work assignments, numbers of machines, and production rates are sequenced so that all operations along the line are compatible. This allows products to be mass-produced in a cost-effective manner.

Henry Ford, created the first moving product assembly line to mass-produce the Model T in 1913. Prior to that, workers used pulley systems to move products from one station to the next. Modern product assembly lines are used in many different industries, increasing output, cutting costs, and boosting profits. According to Ford, the principles of designing a product assembly line are to place the tools and workers in the sequence of the operation so that each component part can travel the least possible distance and result in the most efficient setup possible.

UNDERSTANDING PRODUCT ASSEMBLY LINES

An effective product assembly line divides the processes to break up the manufacture of a product into steps that are completed in a pre-defined sequence. Product assembly lines are the most commonly used method in the mass production of products. Determining what individual tasks must be completed, when they need to be completed, and who will complete them is a crucial step in establishing an effective product assembly line. Complicated products are broken down into components that machines and workers can quickly assemble. Industrial engineers analyze a product and its design in order to determine assembly order, as well as to determine issues that can affect each task. Each task is categorized as either manual, robotic or automatic, and then assigned to individual stations along the manufacturing plant floor. In this way, manufacturers are able to reduce labor costs and increase throughput.

Product assembly lines are designed for the sequential organization of workers, tools, machines, and parts. The motion of workers is minimized to the greatest extent possible. Each worker typically performs one simple operation and job rotation strategies are applied to increase job satisfaction and add diversity.

Product assembly line design and balancing is a mathematical challenge with the goal of assigning a set of tasks that need to be performed on the work-in-process (WIP) to a sequence of workstations in the most efficient manner possible. Each task requires a given task duration for completion. The assignment of tasks to stations is typically limited by what other tasks need to be completed before a particular task can be initiated and the task’s cycle time which restricts the processing times at each workstation before the work-in-process is moved to the next station. The end result is the most efficient and agile deployment of resources on the plant floor.

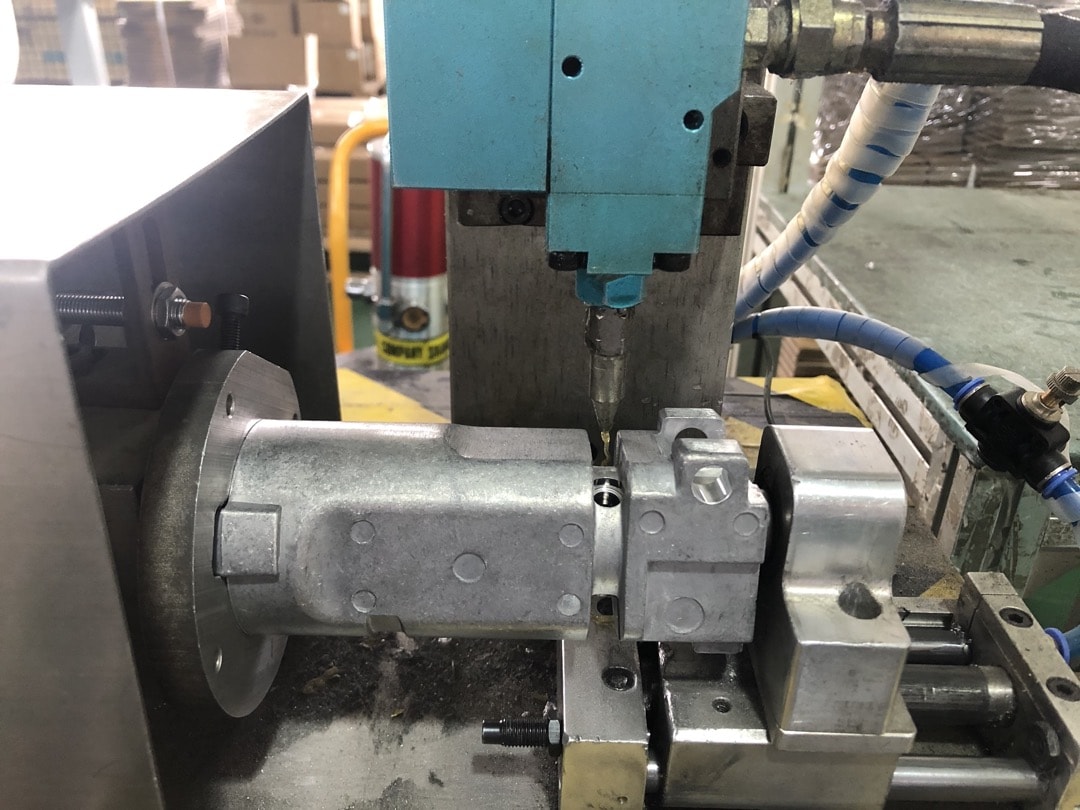

EXPERT PRODUCT ASSEMBLY

Source International offers a wide range of product assembly options and delivers on-time, on-spec, every time. Our high-performance systems are engineered for eco-friendly, low energy consumption with super-accurate repeatability within extremely tight tolerances. Our ISO 9001 certified facilities offer the most advanced, state-of-art assembly equipment giving us the capability to deliver a diverse set of parts for a wide range of industries, including agriculture, automotive, industrial machines, HVAC, and many others. Starting with your AutoCAD, IGES, PDF, or SolidWorks file, our expert team produces your custom parts with tight tolerances and that always meet your specifications. Regardless of the complexity of your design, we’ll find the best way to meet your needs in a timely, cost-effective manner. Contact our team today to check your precision part specifications against our capabilities.

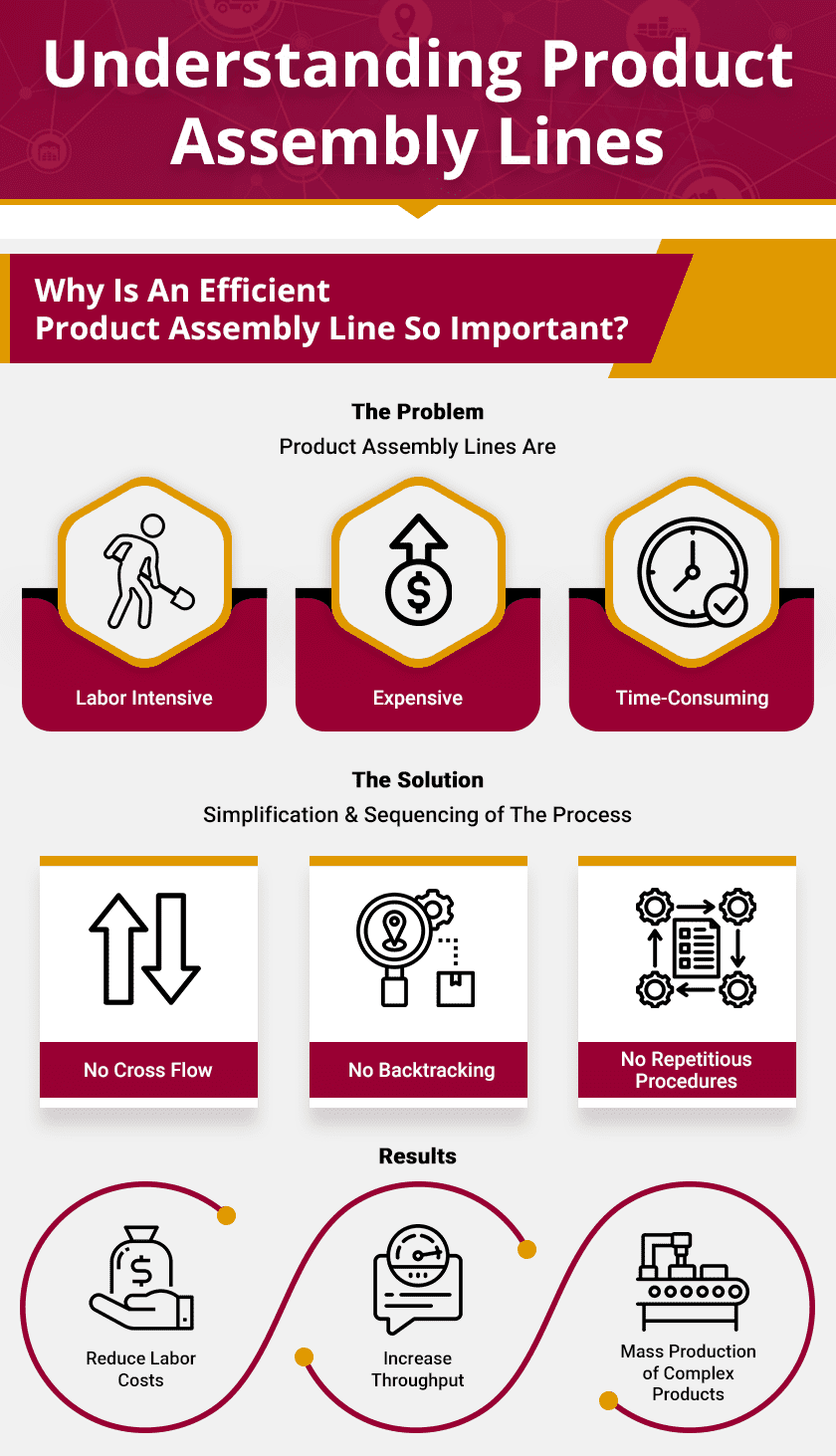

SOURCE HAS OVER 30 YEARS’ EXPERIENCE SOLVING PRODUCT ASSEMBLY CHALLENGES

Source excels in designing and balancing Product Assembly Lines. Depending on the characteristics and volume of the product, Source works with our customers to determine the best methods for the final product assembly and decide whether to build a dedicated assembly line (to achieve maximum capacity and efficiency) or use existing assembly line by modification (to shorten the set-up cost and lead time). Over the last 30 years, Source has designed, set up, and operated hundreds of assembly lines in Asia to support manufacturing of complex products for our customers.

Our people are truly committed to our mission. Each project, each task within a process is an important element of ensuring that our customers receive the highest quality products possible at a sustainable cost. The number of product assembly work stations, number of workers in each station, cycle time of each station and assembly area/layout are evaluated and determined by our Project Engineer/Industrial Engineer; Proper Equipment, Tools and Fixtures/Jigs are selected/built by our Process Engineer to achieve the high repeatability and stability of each step; Assembly Work instructions/In-Process Quality Control (IPQC) List are completed by Process Engineer/Quality Engineer before launching the mass production. A pilot production is typically needed to fine-tune each assembly step to achieve the highest efficiency.

Most recently, our focus has been on completely Automated Product Assembly lines consisting entirely of machines run by machines, with little or no human supervision. In continuous-process industries, product assembly lines are completely mechanized and consist almost entirely of automatic, self-regulating equipment. The development of versatile machinery and the increased use of industrial robots have improved the efficiency of fully automated assembly operations.

We demonstrate our commitment by doing whatever it takes. From start to finish, your job is carefully organized and executed per your specific expectations by people who care. Whatever production challenge you face, our expert creativity, proven techniques and high-quality processes can help you overcome the problem. A few examples of our success stories are detailed in our Case Studies, including mechanical assembly/subassembly for industrial products, home appliances, commercial equipment, and consumer electronics.

SUBSCRIBE TO OUR NEWSLETTER

Talk With Our Supply Chain Experts

SCHEDULE A CALLSOURCE INTERNATIONAL OPTIMIZES SUPPLY CHAINS

Whatever your procurement needs may be, Source International provides commodity and supply management expertise to allow you the most globally competitive prices combined with the best quality (always on-spec) and an on-time delivery record unmatched in the industry.

Send us an email to find out how we can add value to your global supply chain to save you time and money while increasing overall efficiency and product quality.

Spring Clip Installation

Spring Clip Installation In-Line Mechanical Hand Assembly

In-Line Mechanical Hand Assembly Custom Designed Production Jigs

Custom Designed Production Jigs