Forged Products For Industry

Source International – Forged Products

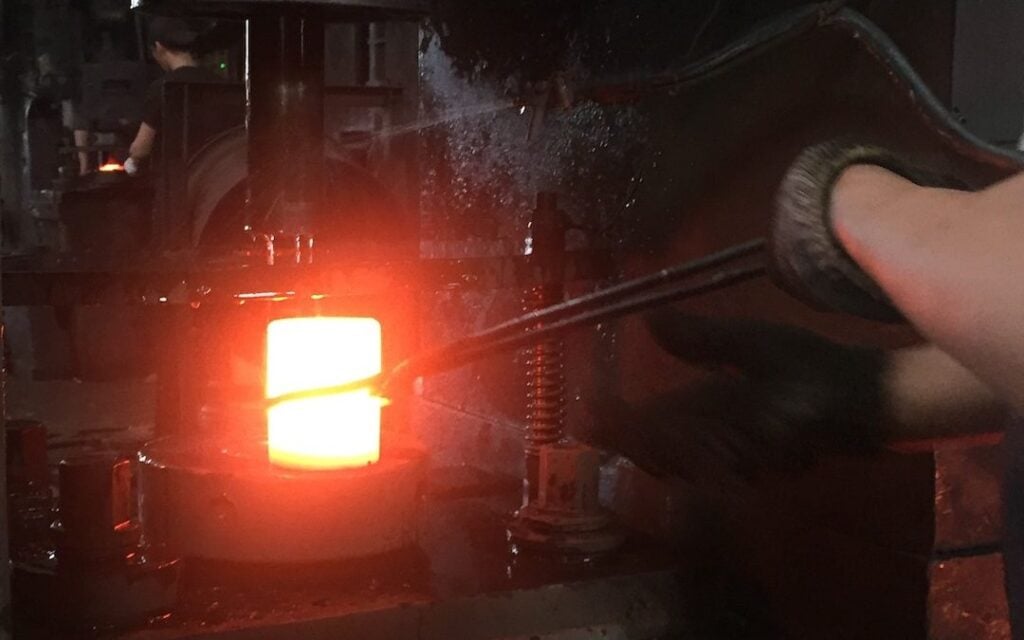

FORGED PRODUCTS AND THE FORGING PROCESS

Forged products (forgings) are pressed, pounded or squeezed under great pressure into high-strength parts that are stronger than cast or machined parts. The forging process is one of the oldest metal-forming processes known to man and is still widely used in modern manufacturing. Because the forging process is capital intensive, we choose well-capitalized partners which have made the proper equipment investments to produce cost-effective forged products in the highly competitive market.

Many metals can be forged including carbon and stainless steels, aluminum, titanium, brass/copper, and alloys of cobalt, nickel or molybdenum. Each metal has distinct characteristics that best apply to specific parts. Our skilled team will help engineer a proper match of specific materials, forging processes, and quantities for your product.

Forged products and parts generally require secondary processes like quenching, heat treatment, CNC machining to achieve tight dimension tolerance and reliable strength. Source International manages an integrated supply chain that brings forged blanks all the way through to finished precision parts through one turnkey sourcing program. We produce reliable parts with good strength in an efficient and cost-effective, sustainable way.

Our ISO 9001 certified facilities focus on the most advanced, state-of-art forging equipment with machines ranging in size from 125 tons to 50,000 tons giving us the capability to deliver a diverse set of parts for a wide range of industries, including agriculture, automotive, industrial machines, and many others.

Starting with your AutoCAD, IGES, PDF, or SolidWorks file, our expert team produces your custom parts with tight tolerances and that always meet your specifications. Regardless of the complexity of your design, we’ll find the best way to meet your needs in a timely, cost-effective manner.

Check out the links at Forging.Org for a good overview of the forging process and materials.

FORGING EQUIPMENT OVERVIEW

Our forging processes include open die forging, closed die forging, and cold forging. Capabilities include hammering, mechanical, hydraulic pressing, upsetting, and bending. In-house machining is used for finishing operations. Forgings range from 1/2 pound to over 500 pounds.

Most of our forgings are done as hot work, at temperatures up to 2300 degrees F, however, some small, simpler items can also be most efficiently produced by cold forging. Equipment and drive systems vary and are updated all the time but we most often produce forgings using the following pieces of equipment:

- Hammers with a driving force of up to 20,000 tons pound the metal into shape with controlled high pressure impact blows.

- Hydraulic Presses with a driving force of up to 50,000 tons, squeeze the metal into shape vertically with controlled high pressure.

Heating:

- 1250kW Induction Heating Billet Furnaces

- 400kW Induction Heating Billet Furnaces

- 2000 kW Elotherm Billet Furnaces

Presses:

- 4000 Ton Forging Presses

- 2500 Ton Forging Presses

- 1600 Ton Forging Presses

- 1300 Ton Forging Presses

- 600 Ton Trim Presses

- 350 Ton Trim Presses

- 200 Ton Trim Presses

- 125 Ton Trim Presses

OPEN DIE FORGING

Open die forgings are produced using flat dies with no precut profiles in the dies. Parts are hammered or pressed and progressively worked into the desired shape between flat-faced dies by timed movements. Using a sequence of dies, multiple open die forging operations can be combined to produce the required shape.

Open-die forging can produce forgings from a few pounds up to more than 150 tons. When optimum structural integrity is needed, the wide size capability of open-die forging makes it the clear process choice over non-forging alternatives. In fact, open-die forgings are limited only by the size of the starting stock.

Our open-die shape capability includes round, square, rectangular, hexagonal bars and other basic shapes to produce step shafts solid shafts (spindles or rotors), hollow cylindrical shapes, contour-formed metal pressure vessel shells, and other shapes and design features.

CLOSED DIE FORGING

Closed die forgings (aka Impression die forgings) are produced by pounding or hydraulically pressing metal between two dies that contain a precut profile of the desired part. Generally, two dies containing impressions of the part shape are brought together as forging stock undergoes forming. The closed die forging process can yield more complex shapes and closer tolerances than open die forging processes and incorporate all kinds of design elements such as flanges, protrusions, holes, cavities, pockets, ribs, bosses, etc.

Closed (impression) die forging can produce an almost limitless variety of 3-D shapes that range in weight from a few ounces up to more than 25 tons produced on hydraulic presses, mechanical presses and hammers, with capacities up to 50,000 tons. The process helps create a relatively complex shape with less scrap and tighter tolerance, and is economical for high volume production, comparing to traditional open die forging.

COLD FORGING

Cold forgings normally include several processes including bending, cold drawing, cold heading, coining, punching, thread rolling, and extrusions to yield a diverse range of part shapes at temperatures from ambient to warm forging at several hundred degrees F. Warm forging practices are selected over cold forging especially for higher carbon grades of steel or to eliminate down line process annealing.

Cold forged part shapes are often shaft-like, cup-shaped, hollow parts with stems and shafts, all kinds of headed parts and bent configurations and are most cost-effective in the range of 10 pounds or less. Additional value and functionality are gained when built-in flanges and bosses are incorporated in the parts like those supplied for automotive steering and suspension parts, antilock-braking systems, hardware, fasteners, and other applications where high strength, close tolerances and volume production make them an economical choice.

Our seasoned engineer and quality team will make sure that the proper material and forging process is used for the quantity, price target, and functionality that you require. Just tell us your requirements and we’ll take it from there to deliver your parts on time, on spec and on budget every time!

SUBSCRIBE TO OUR NEWSLETTER

Precision Forged Product Applications

Source International offers a wide range of precision forged products and parts and packaging and delivers on-time, on-spec, every time.

Source International has been producing forged parts for the U.S. industry for more than 30 years. Some of the largest customer markets include national defense, automotive, and agriculture, construction, mining, material handling, and general industrial equipment.

Source International makes it easy for top quality, custom components or assemblies to be shipped directly from the factory to you. We enable you to enjoy the benefits of working with low-cost offshore suppliers, while encountering none of the problems.

Our Process:

- Send Us Your Drawings

- We Quote A Product Supply Program That Meets your Needs

- We Manufacture and Package to Your Specs and Ship On-Time

- Delivered Directly to Your Loading Dock

Your Benefits:

- 10% to 50% Savings

- Improved Product Quality

- Scheduling and Delivery to Meet Your Needs

- A Single Point of Contact for a Complete Sourcing Solution

Our high-performance systems are engineered for eco-friendly, low energy consumption with super-accurate repeatability within extremely tight tolerances. Contact our team today to check your precision part specifications against our capabilities.

Part Design & Prototyping

Parts should be designed from day one with the forging process in mind to simplify the geometry and minimize assembly. To the extent that you can design hand labor and assembly out of the process you will save money on the cost of labor and pay dividends down the road. Source International’s forging product expertise can help you with that. Once the preliminary design of the part has been decided upon, using a 3D Printer, CNC machining, or other rapid prototyping techniques, we create a one-off of the actual part for evaluation prior to tool making. While oftentimes, the prototype is in a different material than the final part will be constructed in, seeing and holding the physical part leads to insights that are not as obvious in a digital file and facilitates the approval process. A new part will typically go through various iterations and prototypes before the final design is approved and released for production.

Talk With Our Supply Chain Experts

SCHEDULE A CALLSOURCE INTERNATIONAL OPTIMIZES SUPPLY CHAINS

Whatever your procurement needs may be, Source International provides commodity and supply management expertise to allow you the most globally competitive prices combined with the best quality (always on-spec) and an on-time delivery record unmatched in the industry.

Send us an email to find out how we can add value to your global supply chain to save you time and money while increasing overall efficiency and product quality.

Loading The Billet

Loading The Billet Die Cooling

Die Cooling Removing Part From Die

Removing Part From Die Aluminum Forging

Aluminum Forging