OEM vs. ODM in Manufacturing

Original equipment manufacturers (OEMs) and original design manufacturers (ODMs) play a critical role in helping businesses bring new products to market. Although these terms are often used interchangeably, they have key distinctions in areas such as production, branding, and product development. Here, we’ll dive into the purpose, benefits, and drawbacks of OEMs and ODMs to help you determine which option is best for your contract manufacturing needs.

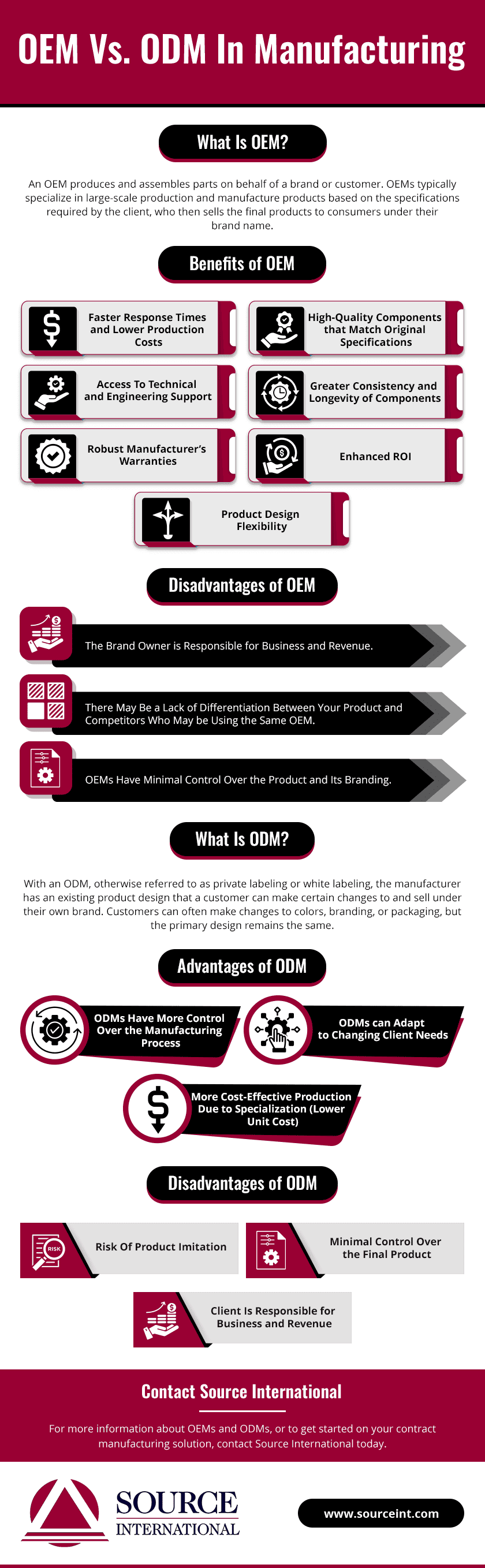

What is OEM?

An OEM produces and assembles parts on behalf of a brand or customer. OEMs typically specialize in large-scale production and manufacture products based on the specifications required by the client, who then sells the final products to consumers under their brand name.

Benefits of OEM

One of the primary benefits of OEMs is that the customer maintains complete creative control over the product design. There are also little to no property restrictions when working with an OEM, meaning you can switch to a different manufacturer down the line if necessary.

Other key benefits of working with an OEM include:

- Faster Response Times and Lower Production Costs

- High-Quality Components that Match Original Specifications

- Access To Technical and Engineering Support

- Greater Consistency and Longevity of Components

- Robust Manufacturer’s Warranties

- Enhanced ROI

- Product Design Flexibility

Disadvantages of OEM

A drawback of OEMs is the amount of resources needed to produce a unique product. This can include research and development costs, as well as the time it takes to create the design before it’s ready for manufacturing. These investments can be quite high and introduce a certain level of risk to a business.

It’s also important to keep the following in mind regarding OEMs:

- The Brand Owner is Responsible for Business and Revenue

- There May Be a Lack of Differentiation Between Your Product and Competitors Who May be Using the Same OEM

- OEMs Have Minimal Control Over the Product and Its Branding

What is ODM?

With an ODM, otherwise referred to as private labeling or white labeling, the manufacturer has an existing product design that a customer can make certain changes to and sell under their own brand. Customers can often make changes to colors, branding, or packaging, but the primary design remains the same.

Advantages of ODM

A main benefit of ODMs is the lower amount of resources a customer needs to create a product. Rather than investing large sums of time and money into developing a new product, customers can use an existing design and focus their resources on marketing strategies.

Other benefits of ODMs include:

- ODMs Have More Control Over the Manufacturing Process

- ODMs can Adapt to Changing Client Needs

- More Cost-Effective Production Due to Specialization (Lower Unit Cost)

Disadvantages of ODM

The drawback of ODMs is that it can be challenging to stand out amongst competitors who offer the same product design at a similar price. This level of pricing competition could result in lower profit margins for your business.

Other disadvantages include:

- Risk Of Product Imitation

- Minimal Control Over the Final Product

- Client Is Responsible for Business and Revenue

Contact Source International

Deciding between OEMs vs. ODMs requires careful consideration of your unique product needs, branding requirements, budget, and more. Founded in 1988, Source International has become one of the largest supply chain management companies in North America. We can provide OEM and ODM contract manufacturing outsourcing services with a proven track record and guaranteed satisfaction.

For more information about OEMs and ODMs, or to get started on your contract manufacturing solution, contact Source International today.