TOOLING FABRICATION OVERVIEW

Tooling fabrication is the prime consideration in making good products. Consider this: If you design and build great tooling, you can make great products; however, poorly made tooling never produces a great product!

Source is a leader in tooling fabrication, design, and engineering. We offer our customers better tooling designs with competitive pricing and always the highest quality, with long usable life. Our diverse knowledge and craftsmanship in tooling fabrication and in building all types of production molds, dies, and jigs, means we can offer the right tooling fabrication solutions. As your full-service provider of production molds, tooling and jigs, our expert project managers integrate product development and manufacturing to deliver custom OEM products ready for mass production. Our commitment is to always deliver quality, innovation, and reliability.

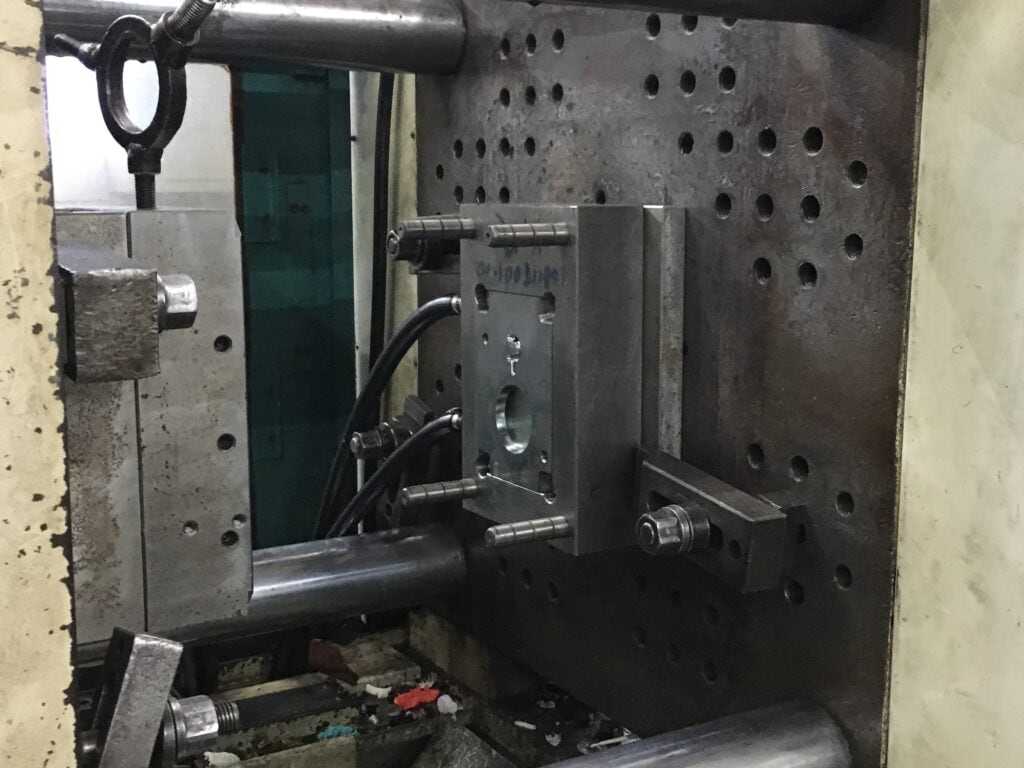

Tooling Fabrication and Mold Making

Tooling fabrication is a core competency at Source International. You see, we have no products of our own. All our production is custom produced to our specifications, and in most cases this requires custom-made molds, tooling, and production jigs to be developed. Our molds and tools are all precision made using the best materials and the latest technologies. We make molds for our own production, and we also make molds for export to others. Below are just a few of the types of tooling that we make:

- Injection Molds

- Casting & Forging Molds

- Compression Molds

- Extrusion Dies

- Stamping Tools

- Production Jigs

- EDM, Wire Cutting, CNC

- DME or Metric Standards

It all starts with the design of the tool. Our tooling fabrication engineers are committed to continuous improvement and use the latest CAD/CAM systems to meet the ever-changing needs of our customers. Our customers rely on us for advice in all phases of their tooling fabrication requirements, and we deliver!

The product part cost is highly influenced by the design of the mold, and our mold engineers provide the creative input necessary to make the best possible decisions, giving confidence, peace of mind, and reliability.

Over the years, Source has earned the trust of the toughest, most demanding customers in the business—mold by mold. Our engineers understand the demands of today’s exacting tooling requirements.

ONCE THE TOOLS ARE COMPLETED, WE BEGIN MASS PRODUCTION AND OUR QUALITY ASSURANCE WORK

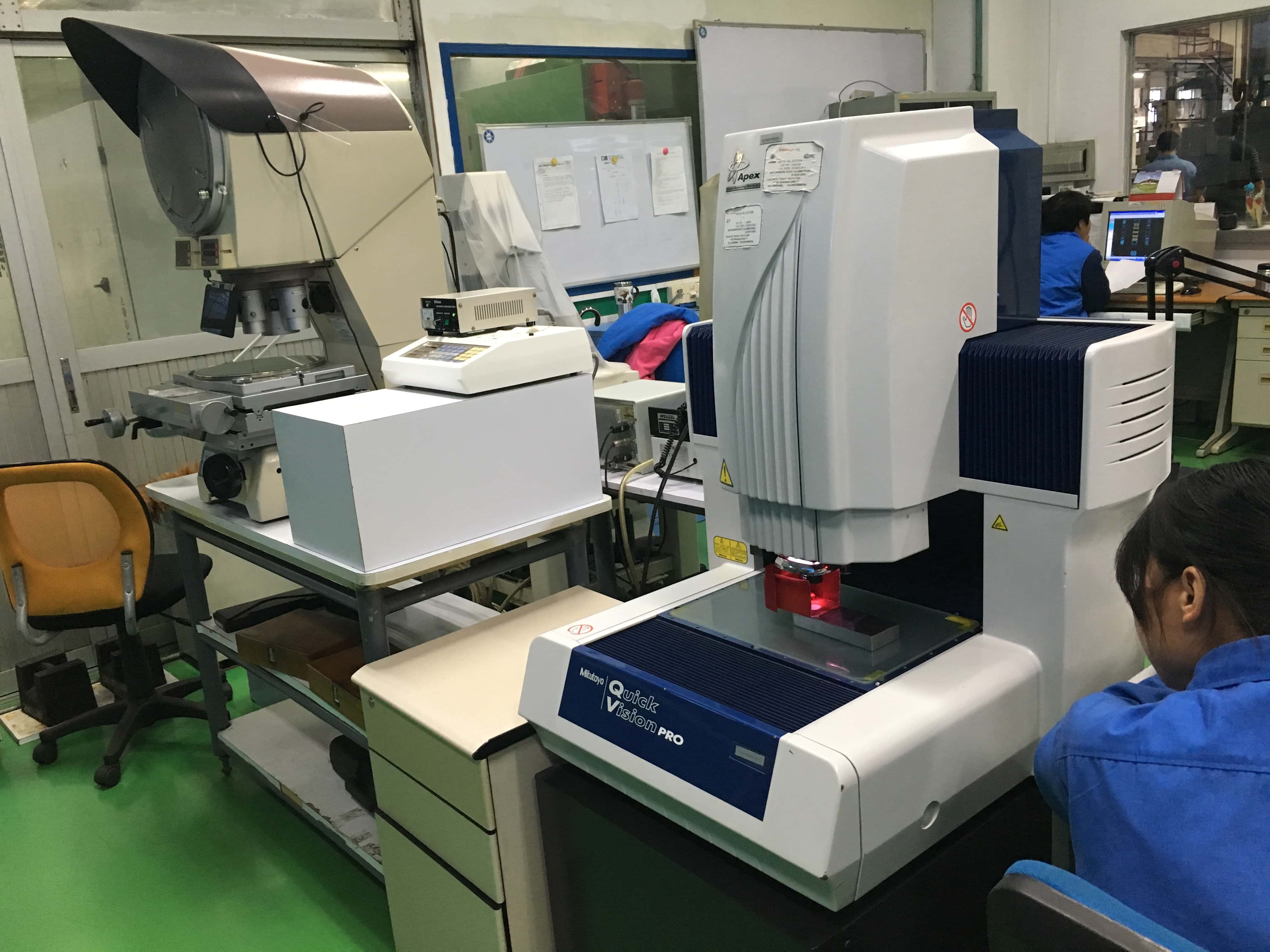

OUR WORLD CLASS TOOLING WORKSHOP

Whatever your tooling application requires, at Source we do it all…and we do it better. We combine an experienced design and engineering team with highly advanced technology and best-in-class equipment. At every step, you can expect superb consultation, attention to detail and customized services that meet your needs. We produce quality results and keep you updated every step of the way.

Our attention to detail in tooling fabrication and our manufacturing experience and knowledge give you an edge to create precision components with component interchangeability to lower maintenance costs, increase mold life, and provide more consistent product quality.

Scroll through our photo gallery to see for yourself the quality of our tooling fabrication equipment and workmanship.