What is Supply Chain Resilience?

Supply chain resilience is identified by its ability to either mitigate or quickly recover from most, if not all, supply chain disruptions. The most agile and resilient supply chains are built to do more than just resist and recover. They are designed using processes and technologies that allow them to predict and respond quickly to whatever risks and opportunities the future holds.

As the COVID-19 pandemic has shown us, worldwide global catastrophes can lead to supply chain issues. Other supply chain problems include unforeseen competition, sudden changes in the market, and even modifications in customer behavior. Now more than ever, supply chain resilience is essential if a business hopes to succeed.

Features of a Resilient Supply Chain

A resilient supply chain works by augmenting production with supply chain planning. Some of the features of a resilient supply chain include:

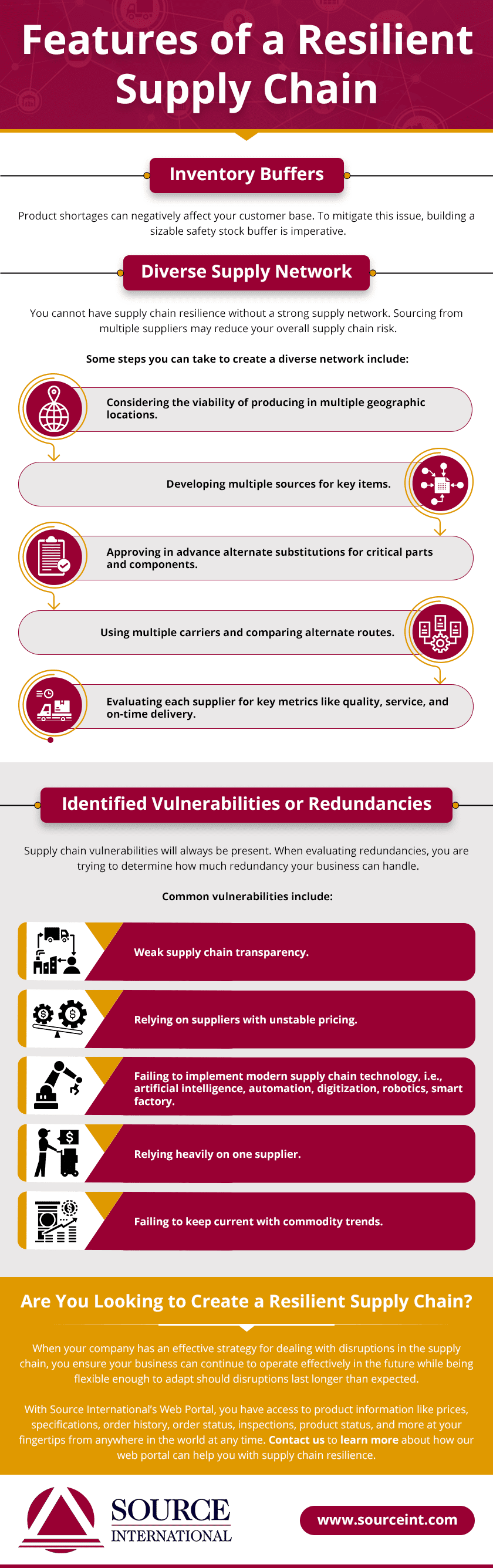

Inventory Buffers

Product shortages can negatively affect your customer base. Customers may become frustrated and seek out other suppliers. To mitigate this issue, building a sizable safety stock buffer is imperative. With an inventory buffer, you can continue to take care of customers while you handle supply issues in the background.

While this measure may seem intimidating due to the required initial investment in the product, it can protect your revenue stream and business reputation in the event of a supply chain disruption.

Diverse Supply Network

You cannot have supply chain resilience without a strong supply network. Sourcing from multiple suppliers may reduce your overall supply chain risk, however, it is important to have an in-depth understanding of each supplier to ensure consistent quality standards. Though vetting each supplier takes some effort, a diverse supply network will afford you business continuity in any circumstance. Some of the steps you can take to create a diverse network include:

- Considering the viability of producing in multiple geographic locations

- Developing multiple sources for key items

- Approving in advance alternate substitutions for critical parts and components

- Using multiple carriers and comparing alternate routes

- Evaluating each supplier for key metrics like quality, service, and on-tim delivery

Identified Vulnerabilities or Redundancies

Perform a risk evaluation and understand where your supply chain is most vulnerable. Unless your product is only available from a single source, you should be able to put measures in place to mitigate these risks.

Supply chain vulnerabilities will always be present. When evaluating redundancies, you are trying to determine how much redundancy your business can handle. Common vulnerabilities include:

- Weak supply chain transparency

- Relying on suppliers with unstable pricing

- Failing to implement modern supply chain technology, i.e., artificial intelligence, automation, digitization, robotics, smart factory

- Relying heavily on one supplier

- Failing to keep current with commodity trends

Example of Resilient Supply Chain

One famous example of supply chain resilience is the case of Nissan and Toyota. After the tsunami and earthquake in Japan in 2011, it became clear that these two companies had a few weaknesses in their supply chain. Nissan was able to build an alternative supply chain network and recover more quickly than Toyota. Toyota eventually built a resilient supply chain and recovered faster when disaster hit again in 2016.

Digital Supply Chains

A digital supply chain offers more visibility into the workings of a supply chain. A digital supply chain focuses more on the customer and integrates internal data and systems with external information.

A study conducted by Bain & Company found the following benefits of a digital supply chain over a traditional supply chain.

- Customers are more satisfied

- Lead times are reduced significantly at almost no extra cost

- Inventory turns increase, increasing cash flow and reducing costs

- There is an increase in perfect order rates

One of the specific strengths of Source International is our tech pack/SIS cloud platform. For each product manufactured, Source International comes up with an exclusive Product Tech Pack (PTP). The PTP is a critical document with all relevant information about your product. Nothing is taken for granted.

Some of the information you might find in the PTP includes:

- Bills of material (BOM)

- Workmanship and appearance

- Function and performance

- Packaging, markings, labeling

- Technical drawings

- Sampling schedule

- Quality plan

Our PTP eliminates guesswork by including every product detail in words, drawings, photos, diagrams, and any other format necessary to communicate the exact requirements.

Are You Looking to Create a Resilient Supply Chain?

When your company has an effective strategy for dealing with disruptions in the supply chain, you ensure your business can continue to operate effectively in the future while being flexible enough to adapt should disruptions last longer than expected.

With Source International’s Web Portal, you have access to product information like prices, specifications, order history, order status, inspections, product status, and more at your fingertips from anywhere in the world at any time. Contact us to learn more about how our web portal can help you with supply chain resilience.