How to Build a Sustainable Supply Chain

Sustainability is about making business decisions that protect and preserve our environment while still offering profitable products and services. It’s also about reducing waste, promoting ethical working conditions, and delivering products and services efficiently.

It’s no surprise that sustainability is closely tied to your supply chain. Here, we will present our top suggestions for assessing your existing supply chain, along with tips for improving its efficiency, transparency, and value.

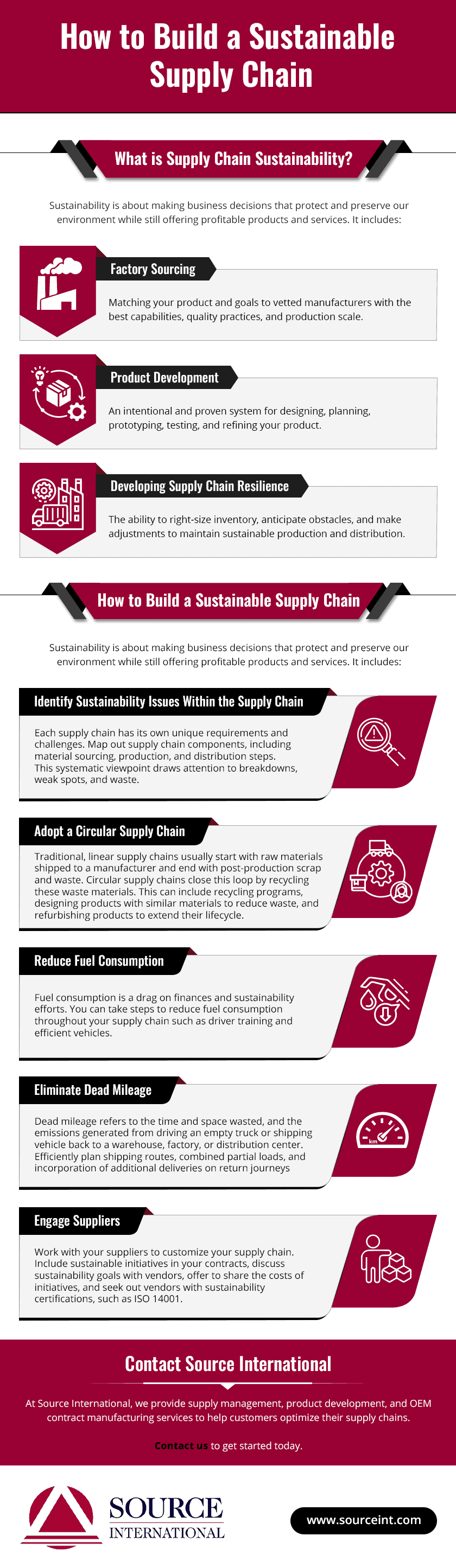

What is Supply Chain Sustainability?

You’ll find environmental supply chain decisions at every turn, including:

- Resource consumption

- Environmentally friendly manufacturing

- Minimizing and managing waste

- Prioritizing “green” materials

- Reducing carbon footprint in production and logistics

- Ethical choices for offshoring or outsourcing

Transparency allows you to make the best choices by giving visibility into material sourcing, manufacturing, and logistics (including last-mile delivery and customer returns). One way to make sure your actions match your stated goals is by working with an experienced partner like Source International for services including:

- Factory sourcing: Matching your product and goals to vetted manufacturers with the best capabilities, quality practices, and production scale.

- Product development: An intentional and proven system for designing, planning, prototyping, testing, and refining your product.

- Developing supply chain resilience: The ability to right-size inventory, anticipate obstacles, and make adjustments to maintain sustainable production and distribution.

How to Build a Sustainable Supply Chain

Every “link” in your supply chain contributes value, or imparts vulnerability to your operations.

Identify Sustainability Issues Within the Supply Chain

You may have one or multiple supply chains, each with unique requirements and challenges. Map out each component of your supply chain(s) including material sourcing, production, and distribution steps. This systematic viewpoint draws attention to breakdowns, weak spots, and waste.

Assess your supply chain for consistent bottlenecks, hard-to-procure materials, complex or highly-skilled manufacturing capabilities you lack, recurring quality issues, and distribution slowdowns. These are good starting points for improvement.

Sustainability also includes your employees and those at other facilities working on your behalf, so consider how supply chain decisions impact things like:

- Exposure to hazardous chemicals and waste products

- Poor working conditions

- Health and safety issues due to materials, equipment, or work environment

Adopt a Circular Supply Chain

Traditional, linear supply chains usually start with raw materials shipped to a manufacturer and end with post-production scrap and waste. In contrast, a circular supply chain aims to reduce waste.

Adding two steps can promote a more circular supply chain. First, develop a plan for recycling or reusing resources. This includes incorporating recycled materials, streamlining with product designs that have parts or materials in common, refurbishing products or equipment to extend their useful lives, or finding ways to use or recycle extra supplies. Second, seek out suppliers that will take back remaining materials for redistribution.

Fuel Consumption

Fuel consumption is a drag on finances and sustainability efforts. You can take steps to reduce fuel consumption throughout your supply chain:

- Driver training: Vehicle operation impacts fuel economy. Provide training in SAFED (Safe and Fuel Efficient Driving) practices for your own drivers, and seek out logistics partners who do the same.

- Efficient vehicles: Whether you purchase your own or outsource logistics, look for fleet vehicles with features that contribute to efficiency such as aerodynamic body designs, appropriately sized cargo and passenger vehicles, and fuel-efficient engines.

Eliminate Dead Mileage

Dead mileage refers to the time and space wasted, and the emissions generated from driving an empty truck or shipping vehicle back to a warehouse, factory, or distribution center.

Sustainability-minded distribution and logistics account for this problem with efficiently planned shipping routes, combined partial loads, and incorporation of additional deliveries on return journeys. Many third-party carriers specialize in this.

Engage Suppliers

Most organizations cannot control every aspect of their supply chain. Complex products, limited material availability, specialized processes, and limited staff mean you’ll rely on other organizations at least part of the time.

You still have options to prioritize sustainability in how you engage with vendors and suppliers. For example:

- Negotiate contracts that include sustainable initiatives

- Discuss your sustainability goals with your vendors frequently

- Recognize sustainably-minded vendors on your website and in customer communications

- Offer to share the costs of sustainability initiatives

- Seek out vendors that are ISO 14001 certified for sustainable practices

Build a Sustainable Supply Chain With Source International

At Source International, we provide supply management, product development, and OEM contract manufacturing services to help customers optimize their supply chains. We’re committed to connecting organizations of all sizes with high-quality, sustainable manufacturing resources.

Contact us today to discuss your next project, learn more about our capabilities, or request a quote.

Comments are closed